TL;DR

- Stoneway Sumner, a sand and gravel operation in a wet climate, struggled with plugging on the wash screen y blinding on the dry screen, crippling production and increasing labor costs.

- They were forced to rely on a portable unit just to meet demand.

- Polydeck provided a targeted solution: POLYDEX screen media with VR apertures on the wash screen, RUBBERDEX rubber media made with FXR elastic rubber formulation on the dry screen, and key machine adjustments.

- The result: tripled production, eliminated plugging and blinding, and a dramatic drop in maintenance effort.

Screen Plugging and Blinding in Wet Conditions: A Costly and Common Problem

Blinding and plugging are among the most frequent causes of downtime in sand and gravel operations—especially when moisture content is high and material is sticky or near-size. Screens can become clogged quickly, reducing open area, increasing recirculating loads, and demanding constant cleanup just to stay operational.

That’s exactly what was happening at Stoneway Sumner, a sand and gravel plant in a moisture-rich environment. Despite quality material and high feed rates, the wrong screen media was holding back the entire operation.

The Challenge: Low Efficiency, High Labor, and a Backup Plant Just to Keep Up

Stoneway Sumner was facing serious operational challenges:

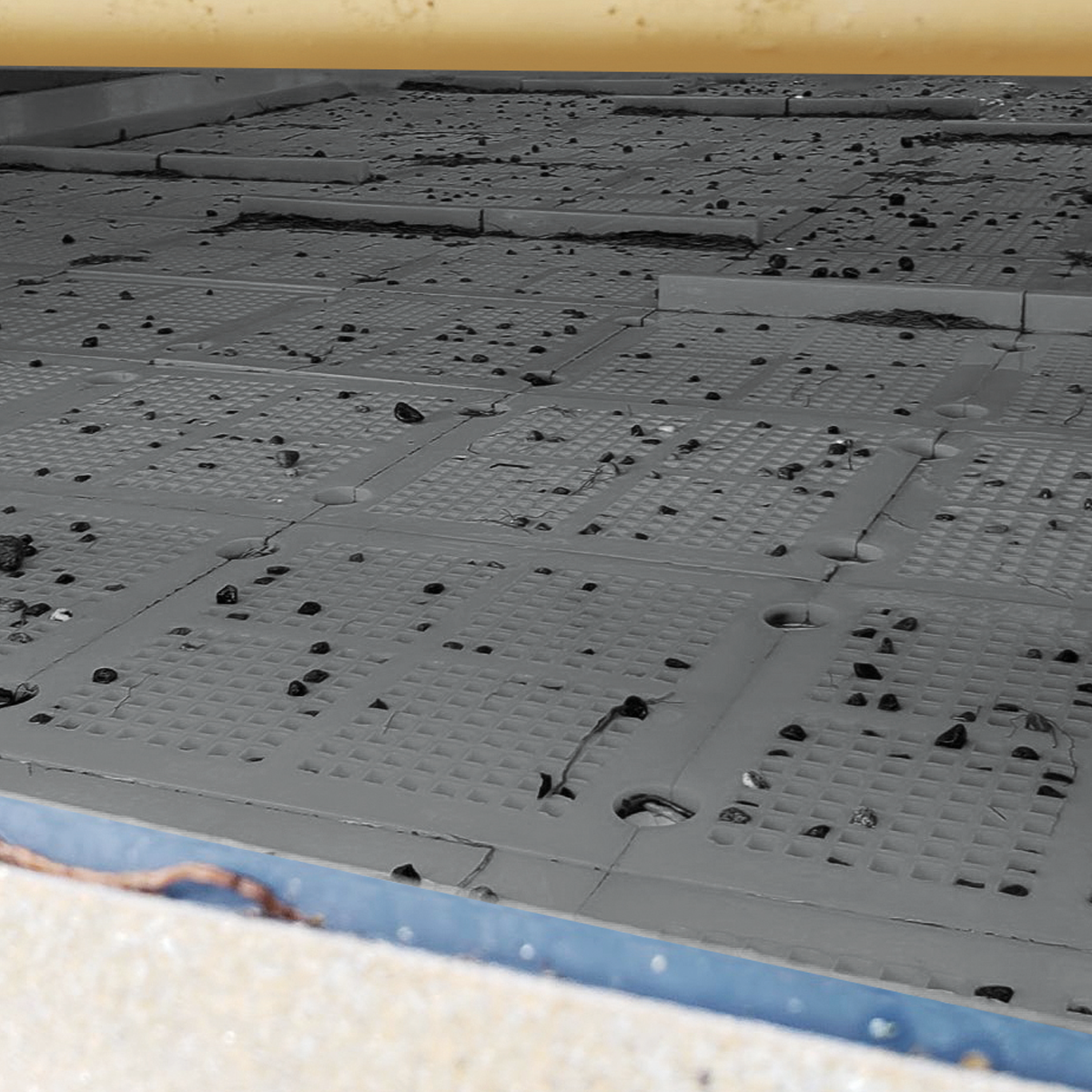

- The dry screen was overwhelmed by blinding

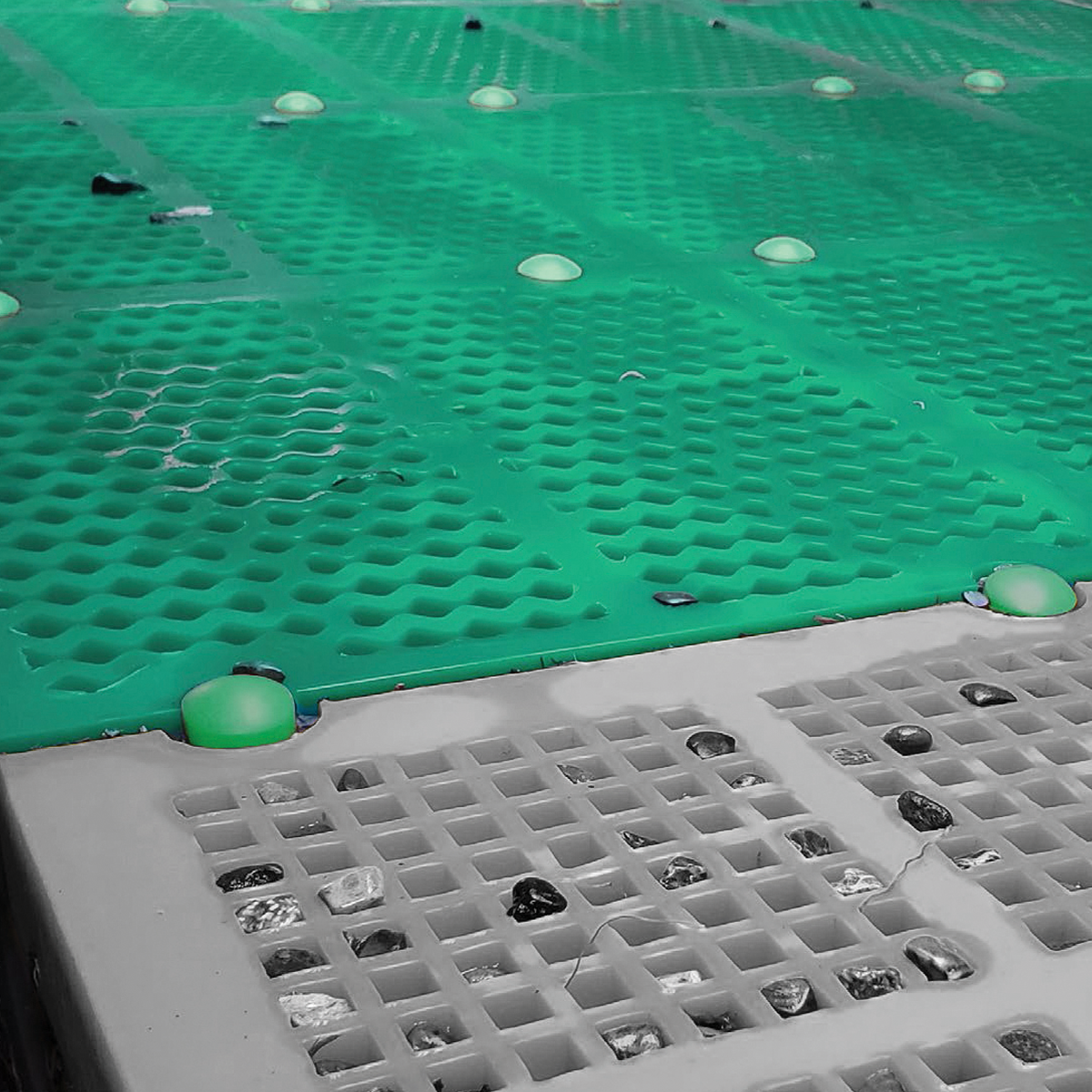

- The wash screen was constantly plugging, restricting flow

- Labor demands exceeded the value of the product being produced

- A portable plant had to be brought in to keep up with production targets

- Traditional fixes and advice from the plant builder had failed

Feed was steady—400 TPH to the dry screen and 450 TPH to the wash screen—but throughput was choked by media that wasn’t suited to the site’s material.

The Solution: Screen Media Matched to Material Behavior

Polydeck’s team quickly diagnosed the issue: the screens weren’t the problem—the media was. Stoneway Sumner needed a solution tailored to their local conditions and feed characteristics.

Wash Screen:

- Increased aperture size on the top deck

- Installed POLYDEX screen media with VR apertures on the middle and bottom decks to introduce secondary motion and dislodge plugging

Dry Screen:

- Installed RUBBERDEX rubber media made with FXR elastic rubber formulation across all decks

- Adjusted the machine’s stroke (reduced) and screen speed (increased) to improve material stratification

All changes were completed using Polydeck’s modular media system—quick to implement, low impact, and fully compatible with the plant’s existing setup.

The Results: Tripled Production and Zero Plugging

Once the new media was installed, Stoneway Sumner saw immediate improvements in screening performance:

- Production tripled, eliminating the need for the portable unit

- Plugging was eliminated on the wash screen

- Blinding was resolved on the dry screen

- Target gradations were consistently achieved

- Recirculating load dropped significantly

- Material spillage stopped

- Housekeeping and maintenance labor were drastically reduced

Why It Worked: Understanding the Material, Not Just the Machine

This wasn’t a hardware issue—it was a mismatch between media design and material behavior.

The original media simply wasn’t made for sticky, wet feed. Once Polydeck aligned the media’s flexibility, aperture design, and screen motion to match the material, performance rebounded instantly. Stoneway Sumner didn’t need a rebuild—they needed a better fit.

It’s a helpful reminder that screen performance depends on matching the media to the material—not just the machine.

Frequently Asked Question

What causes screen plugging and blinding in wet conditions?

Blinding and plugging occur when sticky, high-moisture or near-size material clogs screen apertures. This reduces open area and halts material flow. The key to avoiding this is using screen media designed with the right bridge height, taper, flexibility, and formulation to keep apertures clear—even under wet and sticky conditions.