RESUMEN

- Nugent Sand & Gravel, a Kentucky producer unloading 15–20 barges per day, struggled with severe hopper wear and constant repairs.

- Years of welded AR-plate patching created sharp edges, safety hazards, and frequent maintenance downtime.

- Polydeck installed 2″ PROTEX® RL rubber liners in modular 1×1 and 1×2 ft panels to replace steel patchwork.

- The bolt-in liners eliminated welding, simplified maintenance, and delivered a consistent wear surface.

- Maintenance frequency dropped dramatically, inspections became rare, and PROTEX® RL was later standardized plant-wide.

The Hidden Cost of Patch Repairs

In high-volume sand and gravel operations, receiving hoppers absorb constant impact from heavy material flow. A common approach to managing this wear is welding steel patches over damaged areas. While effective in the short term, repeated patching often leads to uneven surfaces, increased safety risks, and a maintenance cycle that becomes progressively more disruptive over time.

As production demands increase, these legacy repair methods can quietly drive downtime, labor exposure, and inefficiency—prompting many operators to reconsider how they manage wear in high-impact zones.

The Challenge: A Reactive Hopper Repair Cycle

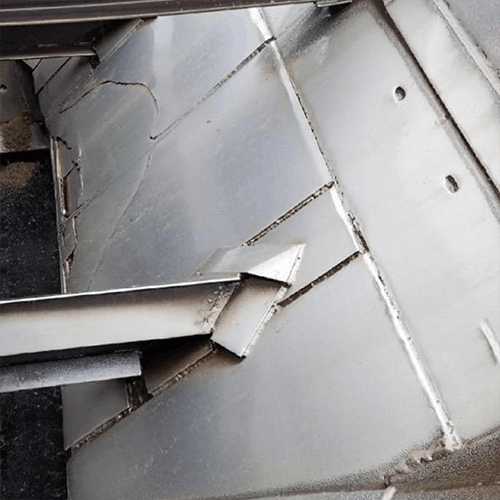

At Nugent Sand & Gravel, repeated welding had become the default response to hopper wear. Over time, this approach introduced new operational and safety concerns.

- Layered AR-plate buildup created uneven, jagged interior surfaces

- Frequent welding and cutting increased downtime and labor exposure

- Sharp edges posed safety risks during inspections and maintenance

- Uneven wear patterns accelerated the need for additional repairs

What began as routine maintenance had evolved into a cycle of constant patching with diminishing returns.

The Solution: Modular Rubber Liners with No Hot Work

To break that cycle, Polydeck recommended 2″ PROTEX® RL rubber liners, a modular, bolt-in lining system designed to absorb impact and eliminate the need for welding.

- Instalado 1×1 ft and 1×2 ft PROTEX® RL liners in the receiving hopper

- Custom-cut liners on-site to match the hopper geometry

- Bolt-in installation eliminated welding and hot work

- Created a uniform, impact-absorbing wear surface across the hopper

Did You Know?

PROTEX® RL provides a fast, safe way to protect hoppers, chutes, and transfer points—reducing downtime and extending wear life without welding or cutting.

The Results: Maintenance Frequency Dramatically Reduced

The impact of the change was immediate. Inspections that once occurred weekly became monthly—and eventually so infrequent they were nearly forgotten. Encouraged by the results, Nugent Sand & Gravel expanded the solution throughout the plant.

- Maintenance downtime dropped sharply, eliminating constant patch repairs

- Extended wear life improved reliability and uptime

- Inspection frequency decreased from weekly to rarely needed

- PROTEX® RL adopted plant-wide across multiple wear zones

- Chutes redesigned around standard liner modules for easier replacement

Why It Worked: Impact Absorption and Standardized Wear Management

The success came from addressing both wear mechanics and maintenance practices.

- Rubber liners absorbed impact energy, reducing abrasive wear

- Modular panels simplified replacements and planning

- Standardized sizing improved consistency across the plant

- Eliminating hot work improved safety and reduced downtime

By replacing reactive repairs with a proactive liner strategy, Nugent Sand & Gravel achieved longer wear life and a more predictable maintenance program.

Preguntas frecuentes

How do rubber liners like PROTEX® RL compare to welded AR plate in high-impact applications?

Rubber liners absorb and distribute impact energy rather than transmitting it through steel. This reduces abrasive wear and metal fatigue while eliminating the need for welding—making maintenance safer, faster, and far less frequent.