TL;DR

- Coeur Wharf Gold Mine faced severe screen plugging and blinding caused by moist material freezing onto screens and cross-members, causing aperture blockage and excessive buildup.

- Competitor wire and polyurethane panels became rigid in freezing conditions, exacerbating plugging and significantly increasing downtime.

- Polydeck Screening Experts retrofitted the decks using flexible RUBBERDEX® modular panels (DMAX and MAXI), strategically zoned for wear management and throughput, supported by custom PIPETOP™ stringers.

- Results included dramatically reduced blinding, improved throughput, extended panel life, simplified maintenance, and consistent gradation control.

Screen Plugging and Blinding in Freezing Conditions: A Hidden Productivity Threat

Freezing temperatures create unique challenges for screening operations in mining. At lower temperatures, moisture-laden materials freeze onto screening surfaces, quickly turning minor operational hiccups into major efficiency issues. The resulting frozen clumps block apertures, drastically reducing open area and screening capacity. For gold mining operations like Coeur Wharf Gold Mine in South Dakota, prolonged cold conditions threatened throughput, quality control, and profitability. To maintain consistent gold recovery, it was critical to address these cold-weather screening challenges head-on.

The Challenge: Material Freezing, Rigid Panels, and Severe Plugging

At Coeur Wharf, freezing conditions severely hampered screening efficiency by triggering a cascade of operational issues.

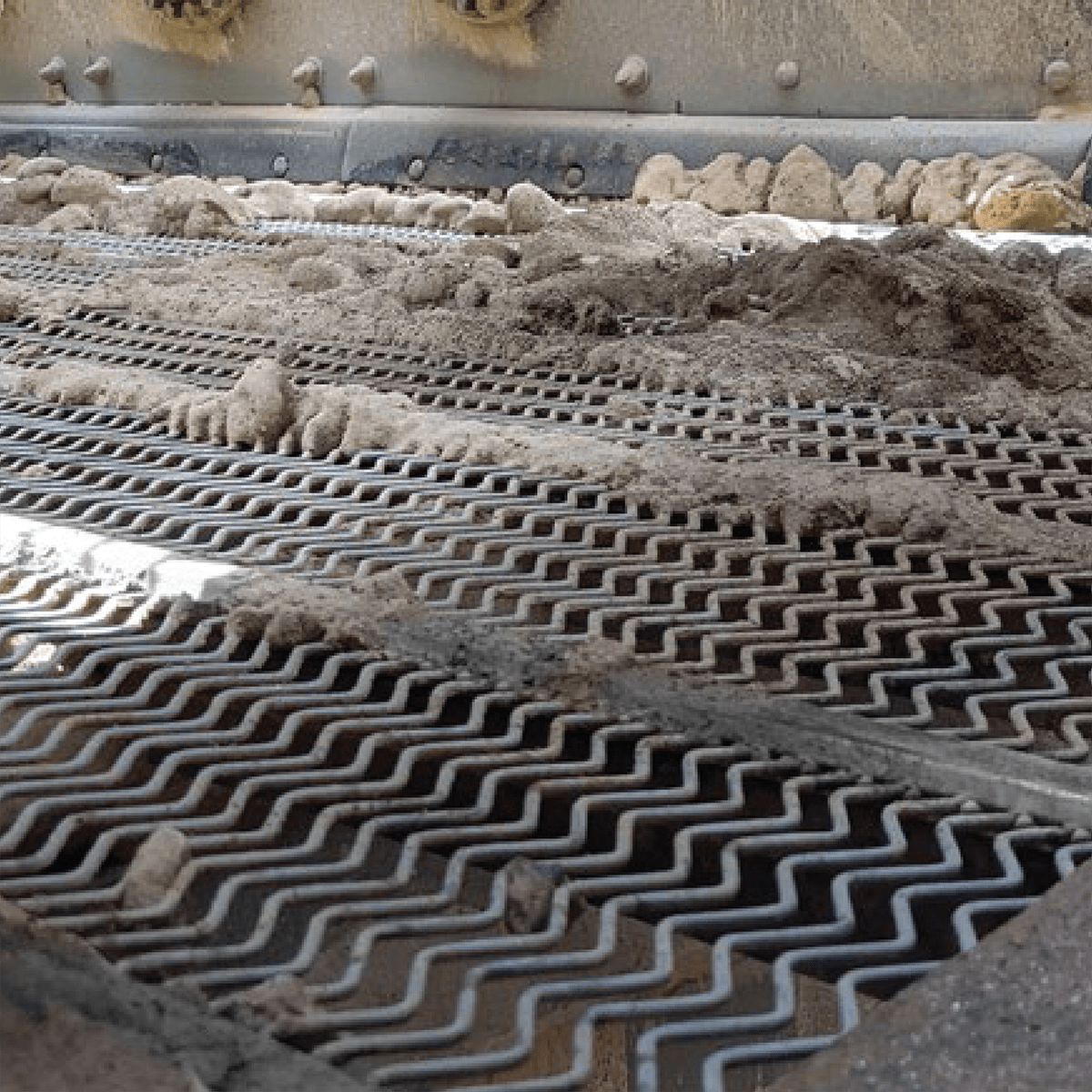

- Frozen Moisture: Moisture in ore froze onto screen surfaces, causing materials to clump together and plug apertures, severely limiting throughput.

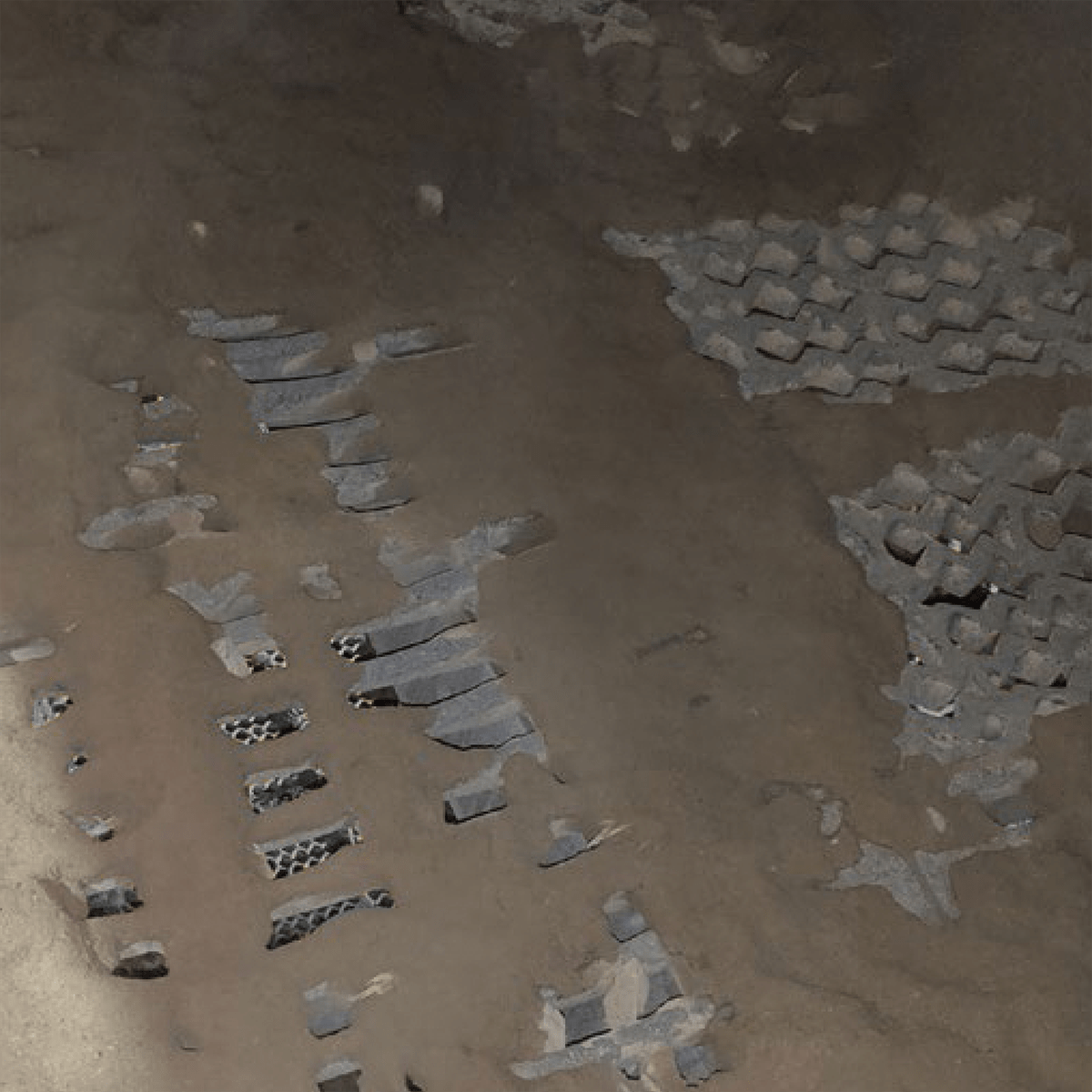

- Frozen Buildup of Fines: Fine materials combined with moisture froze onto cross-members and undersides of panels, creating dense layers of ice that progressively narrowed apertures and amplified plugging.

- Reduced Panel Flexibility: Competitor wire and polyurethane panels became rigid in cold temperatures, significantly reducing their ability to self-clean, clear plugged material, and maintain efficiency.

- Increased Maintenance and Downtime: Rigid panels and persistent frozen buildup required frequent panel replacements, increased downtime, and substantial labor hours for cleaning and maintenance.

Previous attempts to solve these problems using competitor polyurethane and wire panels consistently failed, providing short wear life, poor gradation control, and increased operational downtime.

The Solution: Flexible Modular Retrofit with RUBBERDEX® Panels

Polydeck Screening Experts designed a comprehensive retrofit targeting multiple problematic decks at Coeur Wharf:

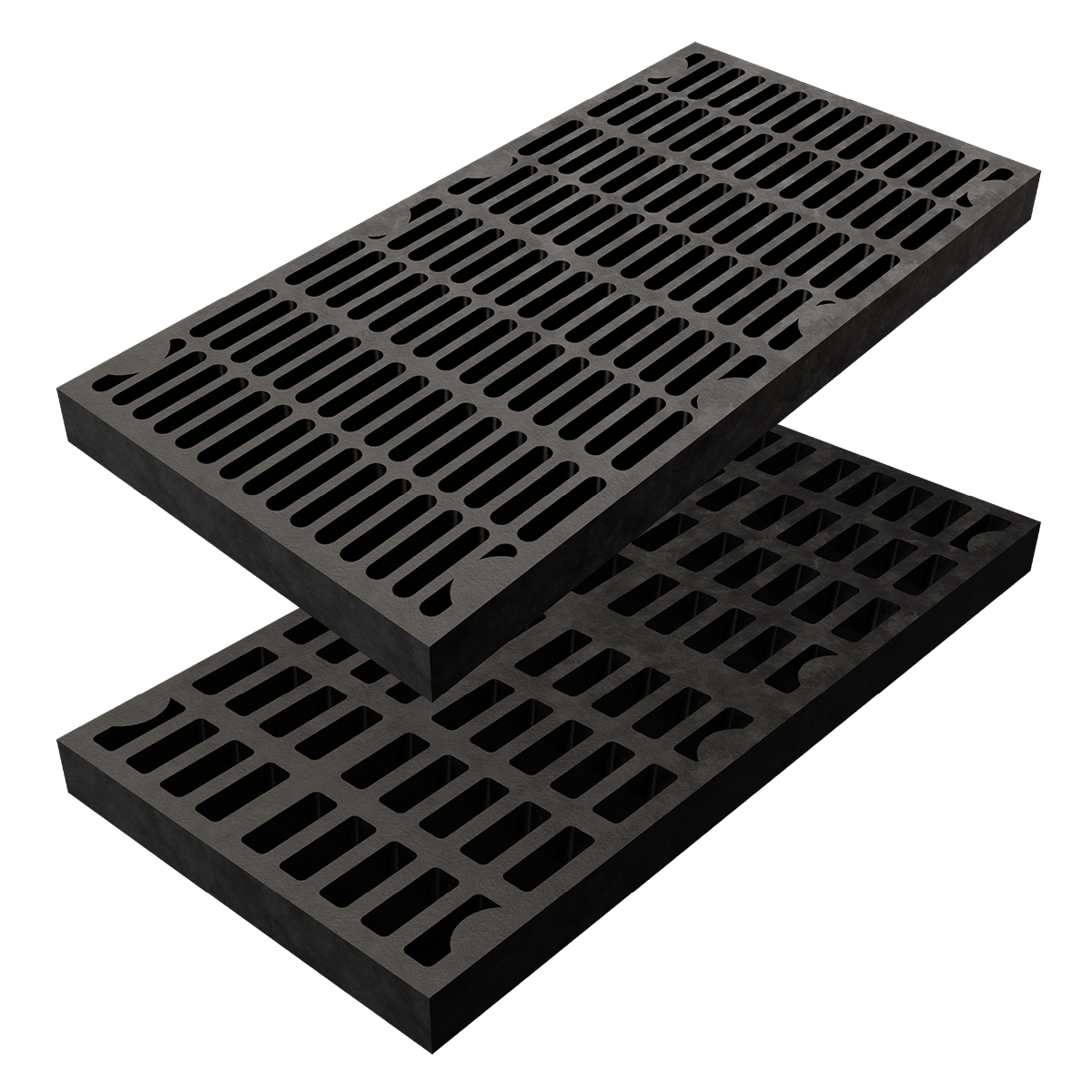

- Retrofitted a total of two tertiary screens y one secondary screen with flexible RUBBERDEX® modular panels (DMAX and MAXI), specifically chosen to minimize plugging and blinding under freezing conditions.

- Implemented strategic panel zoning tailored to each screen:

- Feed zones and mid-deck areas: Installed heavy-duty DMAX ¾” and standard ½” panels for superiorimpact resistance and extended wear life.

- Discharge zones: Utilized panels with precise aperture sizes (9.5 mm) to achieve optimal gradation control and maximize throughput.

- Optimized screen deck structure with custom-designed PIPETOP™ stringers and rounded cross-members, significantly reducing material buildup, streamlining routine maintenance, and easing panel replacements.

Established a scheduled block panel change-out strategy, reducing downtime across multiple screens and simplifying ongoing operations.

The Results: Immediate Operational Improvements and Reduced Downtime

The impact of Polydeck’s targeted solution at Coeur Wharf was immediate and substantial:

- Drastic reduction in screen blinding and plugging issues across multiple decks.

- Significant improvement in overall throughput.

- RUBBERDEX® modular panels outperformed competitor panels, significantly extending wear life.

- Material and ice buildup on cross-members was effectively eliminated, simplifying and speeding up routine maintenance.

- Employee hours dedicated to screen maintenance and cleaning were substantially reduced.

- Consistently achieved and exceeded gradation targets.

“Having Polydeck’s knowledge of screening media has been instrumental in helping us meet our gradation targets, and, as a bonus, we actually have more than the desired passing percentage.”

Why It Worked: Tailored RUBBERDEX® Panel Selection and Modular Adaptability

Polydeck’s retrofit addressed the root causes of plugging and blinding at Coeur Wharf—freezing moisture, fines buildup, and panel rigidity—through careful selection and strategic placement of flexible RUBBERDEX® modular panels (DMAX and MAXI).

The modular layout, made possible by robust PIPETOP™ stringers, allowed easier maintenance, quicker panel replacements, and overall improved system flexibility. By addressing multiple screens simultaneously, Polydeck created comprehensive operational efficiencies, maximizing impact across the mine.

Frequently Asked Question

Why do freezing temperatures cause screen plugging and blinding in mining operations?

Freezing temperatures lead to screen plugging and blinding primarily because moisture in the ore freezes onto the screening surfaces, forming clumps that block apertures. Additionally, frozen fines build up on screen cross-members and panel undersides, gradually narrowing openings. Traditional screen media also becomes rigid in cold conditions, losing its flexibility and further exacerbating plugging and maintenance challenges.