Learn about Polydeck PROTEX from our expert and Northwest Regional Manager for Aggregates, Kendall Herring. Kendall assists the aggregate customers in his region to ensure their operations are optimized for efficiency and throughput in order to meet their production goals. In this blog, Kendall details the benefits of utilizing Polydeck’s custom and in-stock wear liners to preserve durability and reduce maintenance time in aggregate operations.

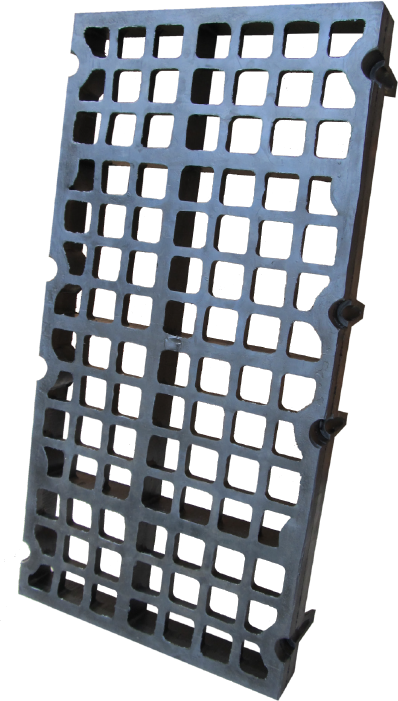

The best-known benefits of Polydeck modular screen media products are wear life, ease of maintenance, and reduced downtime. Why limit these benefits to screen media? Liners are one of the most used products that Polydeck manufactures. Whether you are looking to line a chute, feedbox, discharge lip, conveyor belt liners, hopper or any other wear point, PROTEX is the solution for you.

Are you still using wear metal such as AR plate or other hardened steel? Do your employees spend hours cutting and welding inside narrow chutes? If so, it’s time for you to move into the next generation of wear protection: synthetic liners. Pound for pound, steel products simply cannot compete with the longevity of synthetic materials such as polyurethane, rubber, UHMW, and ceramics. Welding in enclosed areas like chutes is time consuming, awkward, and is a health concern for employees exposed to the fumes. Alternative methods of fastening such as bolt-in, whether with stud bolts or through bolts in countersunk holes, make synthetic liners quick and easy to replace and ensure the fastening will last the life of the panel by protecting the bolt from wear. For even faster attachment, Polydeck’s newly released PROTEX ML (magnetic liners) offer a great option. Simply pry out the old magnetic liner, drop in the new one and fire the plant back up.

For convenient sizes, quick availability, and robust protection Polydeck stocks 1” and 2” thick PROTEX RL (rubber liners) in 12” x 12” and 12” x 24” sizes. This size range allows you to easily create a tiled pattern on your wear points that can be quickly and easily replaced by a single employee. If you forget to order replacements, these liners can be shipped on demand to your site. For those odd bends and angles in your chutes, the stock liners can be cut to fit in the field. Alternatively, Polydeck can create any custom shape and place bolt holes in any position. These custom liners will arrive ready for installation and immediate use in your plant.

Do you need sizes sufficient for your heavy-duty application? Let’s go BIG! Polydeck is capable of making any size and shape rubber panel up to 4” thick and 4’x8’ overall dimensions. One of the most common applications for these custom liners is to fit the feedbox or discharge lip of any screen arrangement to protect these common impact areas. Still need more protection? For the most extreme applications, Polydeck recommends installing the new PROTEX CL (ceramic liners). Depending on your need for impact or abrasion resistance, Polydeck provides ceramics to maximize your wear life and prevent costly downtime.

When you chose to upgrade your wear lining components to Polydeck’s PROTEX options, you will receive expert advice on the best liners for your application, and products designed to last. With over 40 years of experience refining our compounds to provide the industry’s premiere synthetic liners, you can rest assured Polydeck products will last. PROTEX will reduce your operation’s maintenance requirements, improve your operating efficiency, and save you money. Go beyond the screen and experience the durability of PROTEX.

Polydeck Screen Corporation, a global leader in manufacturing synthetic screen media and accessories for the mining, energy and industrial, and aggregate industries, has announced the promotion of Ronald D. Kuehl II to the role of President.

Prior to the announcement, Kuehl served as Executive Vice President of Polydeck since 2017 after joining the company in 2010. His most recent role with Polydeck focused on advancing the global expansion of the company and research and development. The announcement is a result of Polydeck’s continued growth in the markets it serves and its progress as the global leader in screen media.

Kuehl will lead the company as Freissle continues as acting CEO. Kuehl’s role as President will focus on profitable growth, strategic leadership for all employee, commercial, financial, and operational initiatives worldwide, and continually mentoring Polydeck’s leadership team. Freissle will focus on the overall strategic direction of Polydeck, Research & Development initiatives, and ministry involvement in His Way at Work and other Non-Profits.

Kuehl states, "I'm honored to be stepping into the position of President and to continue the legacy of innovation, excellence, and customer focus that has built Polydeck into the synthetic screen media leader it is today. Polydeck’s vision and values are core to our success, and I am committed to supporting and furthering our mission with the support of my team and the entire Polydeck Family. We are truly stronger than we have ever been, and I am humbled to have the opportunity to lead us to the future.”

Freissle states, “I look forward to working together with Ron in his new role and I am excited to support him as he uses his enthusiasm, energy, and experience to continue to fulfill Polydeck's vision of serving our customers and stakeholders with excellence, continuing to grow profitably so that we can care for more people in a way that honors God, while maintaining our position as the leader in our industries."

Kuehl brings with him twenty-five years of experience in screening, going as far back as his first summer job at a quarry-- as a University of Wisconsin student shaking rocks in a batch plant test lab--to his most recent eleven-year tenure at Polydeck. Kuehl holds an MBA from the University of South Carolina (Summa Cum Laude) and a Bachelor of Science in Mechanical Engineering from the University of Wisconsin. He is also certified in Management Development. Kuehl is passionate about ensuring every Polydeck employee understands the purpose and heart of the company and spends his time away from work sponsoring children in Nicaragua through Chosen Children Ministries, supporting the Juvenile Diabetes Research Foundation, and participating in his church worship team as the drummer. Kuehl is a devoted husband and father to four children.

ABOUT POLYDECK

Polydeck Screen Corporation is a family-owned company headquartered in Spartanburg, South Carolina. Founded in 1978, the company is the leading provider of modular synthetic screen media products and accessories for the aggregate, energy and industrial, and mining industries. Polydeck employs more than 340 employees worldwide and serves customers in more than 40 countries.

June is recognized as National Safety Month as a way for employers to set aside time and resources to focus on workplace safety. For Polydeck, workplace safety is fundamental to our culture and is part of our Mission Statement. As a company that regards its employees as its most valuable asset, we consider it the highest responsibility to provide and maintain a safe and welcoming work environment. We’re committed to achieving zero incidents and this month, we’re proud to share some of the ways we have succeeded in achieving the ultimate in workplace safety.

We have a zero-incident safety goal at Polydeck. Zero incidents simply means eliminating events that result in injury, property damage, or lost work time. Achieving a zero-incident safety environment is predominantly dependent on culture. While processes, policies, technology, and mechanisms all contribute to a safer workplace, true safety excellence comes down to every team member’s decision making – which is dictated by our collective attitude toward safety. An attitude and culture of safety is something that each Polydeck team member, whether at our main plant in Spartanburg SC, in our plant in Santiago, Chile or on our Sales Team that’s spread across the world, must commit to and work toward each day on the job. Some examples of how we distribute ownership of safety is by involving our employees in safety audits, hazard analysis tasks, safety champion programs and more. We provide training and opportunities for employees to engage in the company’s safety culture on a regular basis.

Our Sales Team is particularly excited to report zero incidents in 2021 thus far. In addition, our Sales Team members undergo annual MSHA training as part of their commitment to our safety standards. Ron Bennett, Polydeck’s Field Safety Manager, is dedicated to making sure that our Sales Team, who frequent customer sites and are traveling often, are being trained and participate in weekly safety talks distributed across the company. Bennett is also working towards getting all forklift operators at our Distribution Centers OSHA certifications. “Training and being aware of your surroundings are the key to being safe,” Bennett says.

We focus on small, yet impactful changes with total support from our leadership team.

By incorporating “Safety Always” language into our Mission Statement, safety is a tangible focus for the company. Metrics have been put in place to ensure our safety focus is measurable and “wins” are celebrated collectively. In the past 6 months under the direction of our new Director of Operations, Todd Nalepka, we have advanced our safety culture by focusing on initiatives that fall within four main pillars of safety. The pillars we have identified are Setting Expectations, Ensuring Fundamentals, Leading by Example, and Accountability.

Robbie Miller, Environmental, Health, and Safety Manager for Polydeck recalls a standout initiative involving a safety video presentation of Charlie Morecraft’s “Remember Charlie” to production employees. “Charlie’s story was powerful, emotional, and helped change people’s attitude toward safety. This has served as a reminder of why we work safe,” said Miller. Each employee was asked to view the video and make a personal safety pledge in response. The pledges are posted in the canteen at Polydeck headquarters as a reminder of the people counting on each employee, both at work and away from work.

Safety is not something achieved with a simple statement or poster. According to Nalepka, “Achieving safety excellence requires unwavering commitment and constant focus from every team member at Polydeck. While processes & behaviors matter deeply toward advancing our safety environment, the ultimate shift in culture comes with courage. The most impactful ignitors for us to lead with courage are to be continuously reminded of “Our Why” and to respectfully challenge one another. Our stories are all unique. Our motivational factors vary. Our ambitions and hope for the future are different. But deep down inside, “Our Why’s” have much commonality – we strive for excellence in safety to return home to loved ones, enable our team to live fulfilling lives, and navigate our working careers in a healthy manner so we can maximize a joyful retirement. In the simplest form, that’s why workplace safety matters.”

Earlier this year, the South Carolina Chamber of Commerce recognized our efforts to create and maintain a safe workplace by naming us a 2020 Safety Award Winner . While our efforts are never about winning an award, it is the ultimate honor to receive this recognition and be counted among other companies in South Carolina who are leading the charge in safety culture.

In addition to our internal focus on a safe workplace for our employees, Polydeck is proud to offer solutions that increase safety for our customers on their job sites. Wire cloth solutions that require lengthy operational shutdowns, cranes and/or full teams can now be replaced by longer wearing, lighter, easier-to-change modular screen media. Safety and efficiency go hand in hand, and our customers are experiencing both with our revolutionary screen media solutions.

It may sound cliché to say that every month is safety month at Polydeck, but it’s true. It’s proven in our corporate mantra of “Together Strong,” which is the demonstration of our belief that providing high quality products and caring for people are the bedrock of our success. If caring for people is at our core, then safety is non-negotiable. We are fully committed to providing the safest workplace possible for our employees, partners, and vendors, and continuing to innovate to provide products and solutions that improve the safety of our customer’s workplaces as well. Together safe. Together strong.

Wear Liners have the obvious benefit of protection, but some very beneficial value adders like noise reduction, elimination of hot work (welding/cutting), modularity to lower unit weight for handling, and many more. Join Alex Caruana as he shares 3 easy to use Wear Products that you can use to help reduce cost and increase the life of your mining equipment.

The live version of this webinar was presented on Thursday, June 17, 2021 from 1:30pm-2:30pm ET by Alex Caruana. This recorded version available by clicking the link below:

PRESENTER

Alex Caruana,

National Manager- Canadian Aggregates

Recognized as Rock to Road’s Top 10 under 40, and the recipient of OSSGA's 2021 Associate Member of the Year Award, Alex Caruana is a go-to resource for anyone crushing and screening rock! With 15 years in Concrete, Asphalt & Aggregates on both the production and sales sides, Alex has helped some of the largest producers make the most of their processing circuits. With his expertise, a Degree in Civil Engineering, and a focus on Structural & Building Material Studies, Alex brings a refreshing, honest, and unbiased wealth of knowledge to help you drive the most value from your operations! Alex's dedication and passion for helping others has made him one of the top choices for consultation by Aggregate Producers in the industry.

PANELISTS

Marco Dotti,

Director of Sales for Mining in Latin America (LATAM)

With 15+ years of experience in mining, Marco Dotti helps Polydeck customers in Latin America (LATAM) understand their production, maintenance, metallurgy, and reliability needs. Marco has been a leading resource for the largest mining customers in LATAM (Chile, Peru, Panama, and Mexico) and works closely with the Polydeck LATAM engineering and applications teams. His goal is to partner with customers to help them analyze their processes, equipment, and identify possible improvement opportunities. Marco believes that through thorough plant analyses, and strategic, well-defined goals, Polydeck can help customers achieve significant results in process savings and efficiency.

John Griffith,

Mining Project and Territory Manager

John Griffith is Polydeck’s Mining Project and Territory Manager servicing the eastern Canadian region. With over 38 years of experience in the Mining and Mineral processing industry, John’s expertise lie in coal and mineral beneficiation and equipment troubleshooting experience with various equipment suppliers. His career began in underground coal mining in the eastern part of the United States followed by leadership roles with mining process equipment OEMs such as Deister Concentrator, Stock Equipment, Schenck Process Mining & Beumer Group North America. John joined Polydeck in July of 2014 and is an invaluable resource in the Mining industry.

FOR IMMEDIATE RELEASE

SPARTANBURG, South Carolina (April 9, 2021)

Polydeck, a screen media manufacturer headquartered in Spartanburg, South Carolina, announced today it has been named a South Carolina Chamber of Commerce 2020 Safety Award Winner. The Company was named as a recipient of the award during the Chamber’s annual Safety Awards ceremony, held virtually in March.

The South Carolina Chamber 2020 Safety Award is designed to recognize companies from across South Carolina who exemplify workplace safety and safety culture. The SC Chamber believes in this award as a way to highlight and honor companies who prioritize workplace and safety culture, and contribute to making the state a desirable place to live, work, and do business. Polydeck is among 147 companies across the state who were named as Safety Award recipients at the virtual award ceremony.

Polydeck has created a conscious culture of workplace and employee safety and it is something the company focuses on daily. For Polydeck, its employees are its most valuable asset and the company considers it the highest responsibility to provide and maintain a safe and welcoming work environment. The Company focused on small, yet impactful changes along with total support from its leadership team to earn this award and ultimately create a strong safety culture. By incorporating “Safety First” language into its Mission Statement, Polydeck made safety a tangible focus for the business. Metrics were put in place to ensure the focus was measurable. Every employee is involved in the safety culture, from participation in safety audits, hazard analysis tasks, surveys, employee suggestions, safety champions, and even a focus on employee engagement that reflects a safety aspect.

Polydeck’s leadership team agrees the award builds confidence in the actions that have been put in the place over the past several years. They are encouraged that the award is a testament to Polydeck’s customers, suppliers, and surrounding communities of the company’s commitment to a caring culture that truly values employee safety. Polydeck has a goal of a zero incident workplace and this award is progress toward that audacious goal.

“It is quite an honor to have our culture and focus on safety recognized by the SC Chamber,” said Polydeck Safety Manager Robbie Miller. “However, it’s simply a way of life for us. We recognize that safety begins and ends with each of us. It’s up to everyone at Polydeck, and it shows that everyone agrees when you witness the culture of workplace safety that is evident here on a daily basis. Every employee is empowered and encouraged to initiate conversations and actions to maintain and improve our safety culture. This award is a testament to every employee and their dedication to accomplishing our goals together,” state Miller.

ABOUT POLYDECK

Polydeck Screen Corporation is a family owned company headquartered in Spartanburg, South Carolina. Founded in 1978, the company is the leading provider of modular synthetic screen media products and accessories for the aggregate, energy and industrial, and mining industries. Polydeck employs more than 340 employee worldwide and serves customers in more than 40 countries.

Learn more at https://polydeck.com/ .

The Ontario Stone, Sand & Gravel Association (OSSGA) has named Polydeck's National Manager for Canadian Aggregates, Alex Caruana as its Associate Member of the Year for 2021. The Award, presented annually by OSSGA to one Associate Member, was created to recognize the efforts of associate members who advise, supply and support aggregate producers. The member recognized is often one who is known for productive relationships with both OSSGA members and involvement in their local community while actively shaping a positive image for the aggregate industry in Ontario. Associate Members are critical to the success of the aggregate industry, working alongside producers to provide operational advice, expertise and support.

The OSSGA Associate Member of the Year Award is typically presented at the association’s annual conference, however, due to the pandemic the conference was virtual this year. Polydeck’s Alex Caruana found out he was named Associate Member of the Year when he received a called from OSSGA’s Chairman of the Board of Directors. “It left me speechless. This award isn’t really something you’re working toward or trying to earn. However, now I can see the journey I’ve taken to get to this award. I am beyond honored,” stated Caruana in a recent conversation about the award. Caruana considers being named Associate Member of the Year quite the honor, as it requires nominations from far and wide and is a true testament to his time and investment in his career in the aggregates industry. For Caruana, the award comes with humility and appreciation for his colleagues and peers who deemed him worthy of their nomination.

Alex Caruana, a self-professed rock nerd in his own words, loves working in aggregates. He says it’s an industry that feels like a small world where you get to know everyone. Having started in the industry 15 years ago as a university student, Caruana says it’s the ultimate honor to be recognized by those he shares his work hours with. His career in the aggregates industry began when he was pursuing a Civil Engineering degree and his Dad suggested he get a summer job in construction or an industry related to his chosen field of study. He applied for a job at Dufferin Concrete and was hired as a Quality Control Technician. Caruana enjoyed the job and kept his role at Dufferin for several summers and eventually went to work for Dufferin full time when he graduated. After several years working in the pits and quarries at Dufferin, Caruana began to have interest in working in a different capacity in the industry. This interest led Caruana to Polydeck, where he now helps customers with their screen media needs and production opportunities in the same place where he started his time in the aggregates industry more than 15 years ago.

Thanks to his experience during his university years and afterward, Caruana has an extensive understanding of what his customers require from their operations. His approach as a problem solver is evident to everyone he works with and it’s no secret that he loves his job. His ultimate goal is to take away his customers’ worries about their operational productivity and he does so with a strong understanding of their operations. Caruana works to provide solutions for his customers so they can set up their operation, forget about it, and see the results they’re seeking as quickly as possible. For Caruana, involvement in OSSGA has been icing on the cake of a career he truly loves. It’s provided connections and community involvement that further enhance his passion for helping his customers and the communities he works in. As he says, “I consider it a privilege to have a job I look forward to every single day.” Ask any member of OSSGA and they’ll likely tell you the privilege of knowing Alex Caruana is theirs, as evidenced by this award.

Producers often turn to what has always worked and what they are accustomed to when it comes to selecting their screen media. While wire cloth has its advantages, wire has met its match in Polydeck’s newest offering. Meet DMax, the latest in high performance, extreme open area synthetic modular screening.

At Polydeck, we’re known for relentlessly pursuing solutions to the challenges our customers face. When your operation depends upon the performance of your screen media, nothing less than the best solution is acceptable. DMax, Polydeck’s latest evolution in modular synthetic screen media provides so much throughput advantage, its open area rivals that of wire cloth while providing the durability and benefits often associated with modular synthetic screen media panels.

DMax is the result of Polydeck’s advanced material science technology that balances durability and high open area in screen media construction. This balance provides a better return on investment and a significant increase in throughput where DMax panels are used. Plant Manager Trulane Vanatta recalls the efficiency gained by using DMax panels at Morrison Quarry, “The increase in open area resulted in an 11% increase in the production of profitable 1-in. rock, and reduced fines by nearly 1%.” As any producer knows, even small reductions in fines paired with production increases is incredibly important to an operation’s profitability.

When producers initially began using synthetic screen media, it was in response to the durability the product offered them. DMax achieves the durability producers expect, along with a significant increase in available open area. DMax provides the perfect balance between wear life for uptime, and the health and safety benefits associated with reduced noise and fewer whole deck changeouts. Like all of Polydeck's modular synthetic media, Dmax can be changed out in small sections as screens wear, preventing dangerous and costly shutdowns for larger media changeouts, while preserving the benefits synthetics are known for.

DMax panels are fully customizable, allowing Polydeck’s team of experts to create a solution that meets the unique needs of each operation. Common opening ranges can increase open area by 25-30% against standard synthetics, frequently exceeding wire's actual available open area, which is the open area actually available once bucker bars and other dead spots are accounted for. As every producer knows, open area is directly related to efficiency, thus more open area means a more efficient operation.

A Producer using cone crushers in a closed circuit could benefit significantly from using DMax. The extra open area on the screen preceding the cone crusher allows the product to reach the pile more quickly, instead of the cones. The result is extra capacity for the cone, less fines generated overall, and good salable product to pile sooner and in higher overall splits within the plant. The extra open area provided by DMax means less dust and fines and more clear stone production. This also helps decrease cone crusher wear and reduces overall power consumption since the system is being evacuated more quickly. Reduced power consumption translates to lower operational costs both in energy costs and wear on equipment.

Polydeck’s modular technology allows for easy and safe installation of DMax with other panels and use in zones where efficiency is key. DMax is ideal for use in conjunction with heavier duty panels in feed zones in order to maximize useful available open area.

DMax offers a significant weight reduction benefit over other synthetic screen media options, which reduces component wear on the screen and increases the effect of the vibrating mechanism’s stroke on particle separation. At the end of the day, it all translates to higher production levels with reduced costs.

While there are many applications where DMax can be used, producers win with DMax where there are overall blinding issues or overloaded decks leading to inefficient screening. DMax eliminates blinding and allows for more throughput. With DMax, the right size material goes through the screens, eliminating downstream bottlenecks and increasing tonnage through the plant. When durability, true open area, and reduced downtime come together, efficiency is the ultimate result. Consider DMax, the synthetic screen media that will have you rethinking your wire cloth.

Polydeck expanding operations in Spartanburg County

More than $8.7 million investment creating 45 new jobs

COLUMBIA, S.C. – Polydeck, a leading provider of polyurethane and rubber screen media and specialty screening solutions, is expanding its operations in Spartanburg County. The more than $8.7 million investment will create 45 new jobs.

Polydeck is a family-owned business aimed at providing optimal screening solutions for the aggregate, coal and mining industries around the world. Specifically, Polydeck produces polyurethane and rubber screen media, trommel screens and screening accessories. The company also offers process consulting and screen evaluation services to customers in all three industries. In 1978, Polydeck opened its first U.S. operation in Spartanburg, S.C., and this project marks the company’s eighth expansion.

Located at 1790 Dewberry Road in Spartanburg County, this expansion will allow Polydeck to accommodate significant sales growth.

QUOTES

“For more than 40 years, South Carolina has provided us a positive business environment, and we are pleased to have this opportunity to grow our business base here in Spartanburg. We feel that growth is a direct result of our company vision, which is to serve our customers and stakeholders with excellence to achieve profitable growth which enables us to care for people in a way that honors God. Part of Polydeck’s mission is to improve the lives of our employees, their families and the communities where we work. This expansion not only helps fulfill our mission by impacting and supporting more Upstate residents but will also provide more capacity for our loyal customers and an opportunity to manufacture new innovative screening products. On behalf of the Polydeck team, we are grateful to be part of such a business-friendly community and state.” –Polydeck Screen Corporation President Peter Freissle and Executive Vice President Ronald D. Kuehl II

“While we work hard to recruit new businesses to South Carolina, we work even harder to take care of those that are already here. When established companies like Polydeck continue to expand, it’s a sign our economic development efforts are heading in the right direction.” –Gov. Henry McMaster

“South Carolina’s manufacturing sector continues to grow with great success. Family-owned Polydeck continues to thrive and expand, showing that South Carolina is the ideal place to manufacture and distribute products and that the Palmetto State is ‘Just Right’ for business.” –Secretary of Commerce Bobby Hitt

“We are very pleased that Polydeck chose their Spartanburg County facility for their expansion and the creation of additional jobs. Polydeck is a solid company with a long history of growth and job creation. This project represents Spartanburg County’s commitment to our existing industry.” –Spartanburg County Economic Development Committee Chairman and Economic Futures Group Board Member David Britt

FIVE FAST FACTS

- · Polydeck is expanding operations in Spartanburg County.

- · The more than $8.7 million investment will create 45 new jobs.

- · Polydeck provides optimal screening solutions for the aggregate, energy and industrial, and mining industries.

- · The company is located at 1790 Dewberry Road in Spartanburg County.

- · Individuals interested in joining the Polydeck team can visit https://polydeck.com/about/careers.

Adapted from https://www.sccommerce.com/node/6944

About S.C. Department of Commerce

As South Carolina's leading economic development agency, the Department of Commerce works to recruit new businesses and help existing business grow. S.C. Commerce has recruited world-class companies to South Carolina such as BMW, Boeing, Continental, Giti Tire, LPL Financial Holdings, Mercedes-Benz Vans, Samsung, Toray and Volvo Cars and also supports startups, small and existing business, innovation and rural development initiatives. S.C. Commerce partners with the S.C. Technical College System via readySC to support workforce training and recruiting, and with the S.C. Department of Employment and Workforce, which provides worker training and employment opportunities within the state. With a strong international footprint, the Palmetto State ranked No. 1 in the nation for attracting jobs through foreign investment on a per capita basis in 2018 -- extending its streak of top three finishes since 2011. Additionally, the state has won the Gold or Silver Shovel Award from Area Development magazine every year since 2011; and, in 2017, the state was recognized as Business Facilities' State of the Year. For more information, visit www.SCcommerce.com.

The live version of this webinar was presented on Thursday, March 25th, 2021 from 2-3pm ET by Alex Caruana. This recorded version available by clicking the link below:

This presentation focuses on expanding operators' thinking from strictly open area to the combination of true effective open area, wear life, loss of open area due to blinding, modularity, surface features, spray nozzles, and all considerations necessary to maximize efficiency. While maximizing open area on a screen deck is theoretically going to make the most of a plant's uptime, the multitude of tasks on-site result in imperfect maintenance practices, and hence it is important to balance screen decks to maximize open area whilst minimizing maintenance requirements.

Alex Caruana,

Territory Manager

Recognized as Rock to Road’s Top 10 under 40, and the recipient of OSSGA's 2021 Associate Member of the Year Award, Alex Caruana is a go-to resource for anyone crushing and screening rock!With 15 years in Concrete, Asphalt & Aggregates on both the production and sales sides, Alex has helped some of the largest producers make the most of their processing circuits. With his expertise, a Degree in Civil Engineering, and a focus on Structural & Building Material Studies, Alex brings a refreshing, honest, and unbiased wealth of knowledge to help you drive the most value from your operations! Alex's dedication and passion for helping others has made him one of the top choices for consultation by Aggregate Producers in the industry.