Metaldex XPT

Wire cloth throughput without the tradeoffs.

METALDEX® XPT delivers the open area and throughput operators expect from wire cloth, while eliminating the changeout cycles and early performance fade that limit how long decks can run.

Open area ≥ Wire cloth

Lasts 3x longer than traditional wire cloth

Changeouts in minutes, not hours

What Happens when Familiar Tools Meet Modern Demands?

Wire cloth has earned its reputation as a high-throughput screening surface. For years, it has set the benchmark for open area and material flow. Today, that benchmark is being tested. As run cycles stretch longer and maintenance windows shrink, the limitations built into wire cloth are harder to overlook:

- Gradual degradation makes performance issues harder to detect early.

- Changeouts aren’t always planned.

- Small failures can trigger larger interruptions.

That’s where many operations begin looking for a way to keep the throughput they trust, without inheriting the same tradeoffs.

3 Wire Cloth Myths No One Talks About

Download our free METALDEX XPT slide deck today.

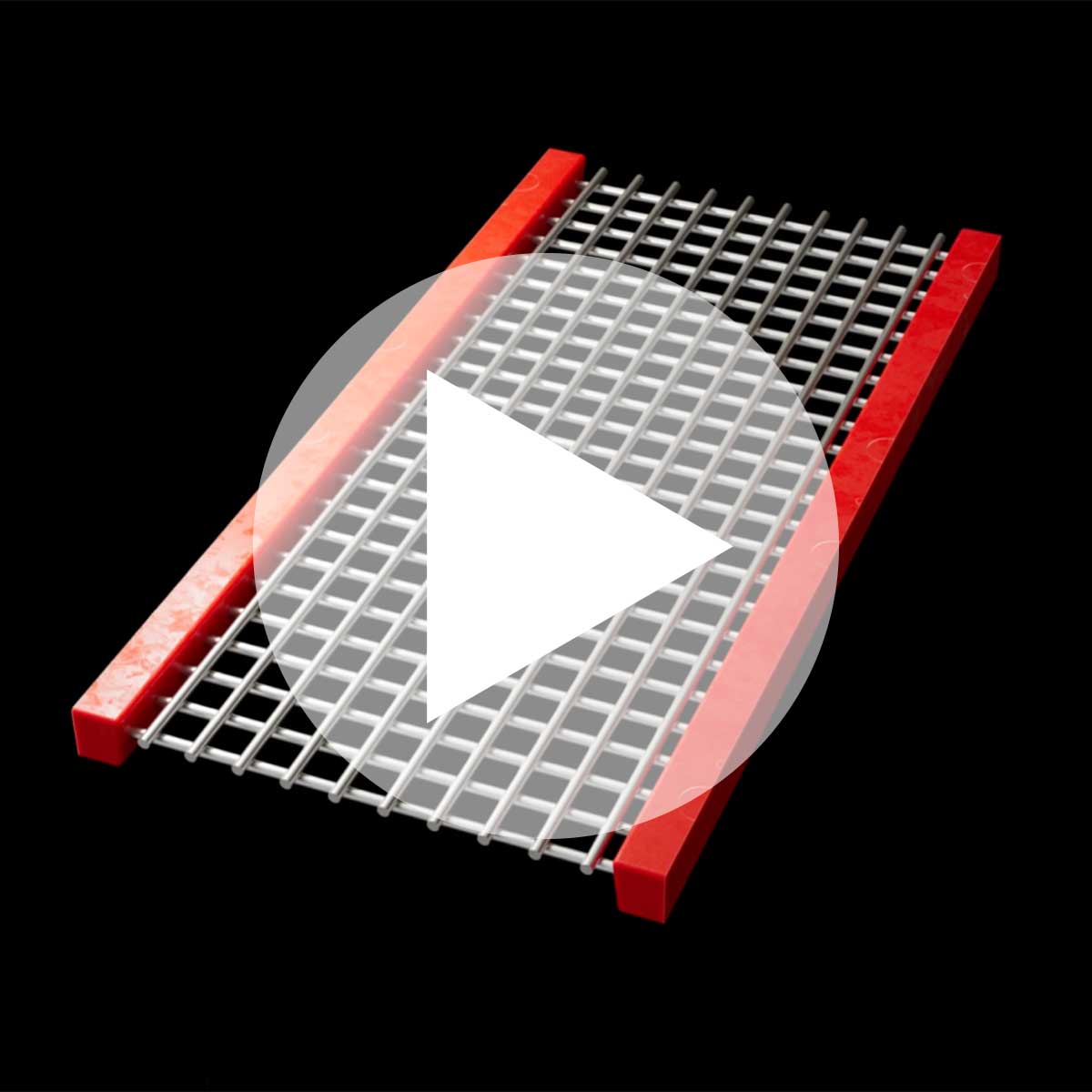

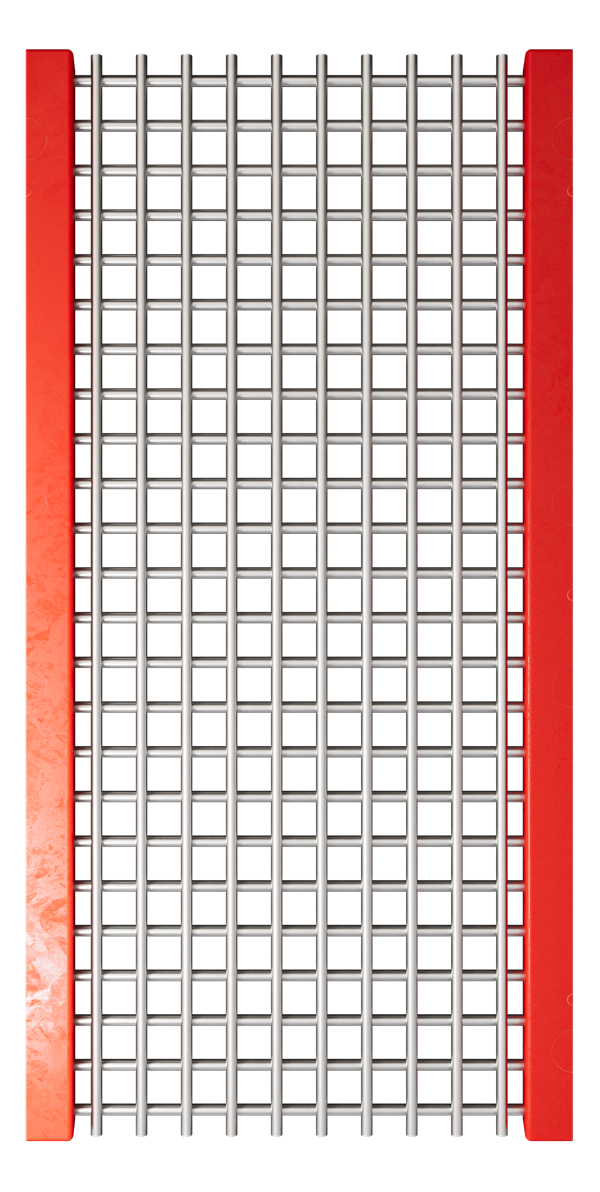

Meet METALDEX XPT

By combining welded wire construction with a modular design, METALDEX XPT helps:

- Maintain the open area and throughput expected from the wire cloth

- Isolate wear to specific sections, rather than replacing full decks

- Plan maintenance more predictably, reducing surprise failures

- Extend usable deck life without sacrificing throughput

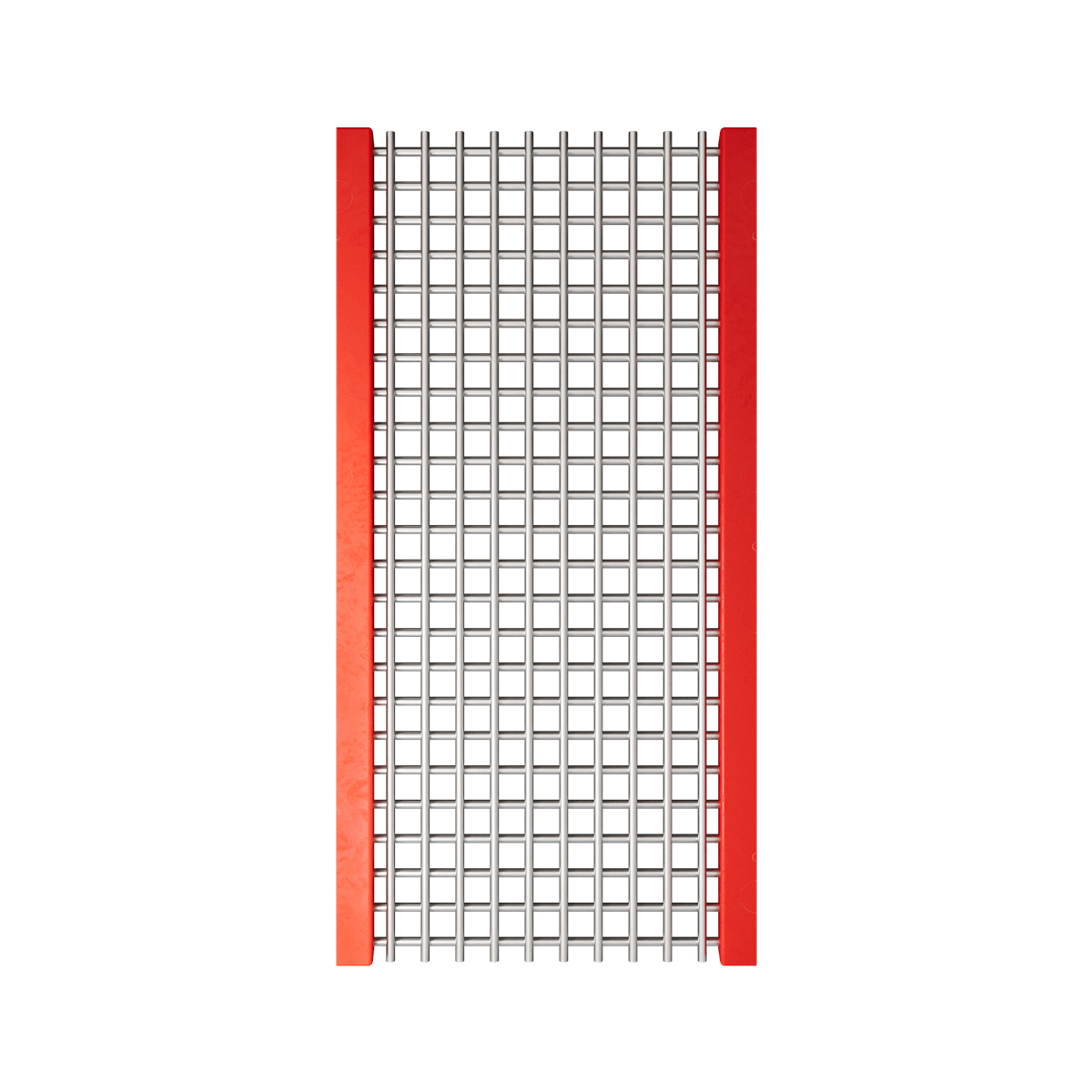

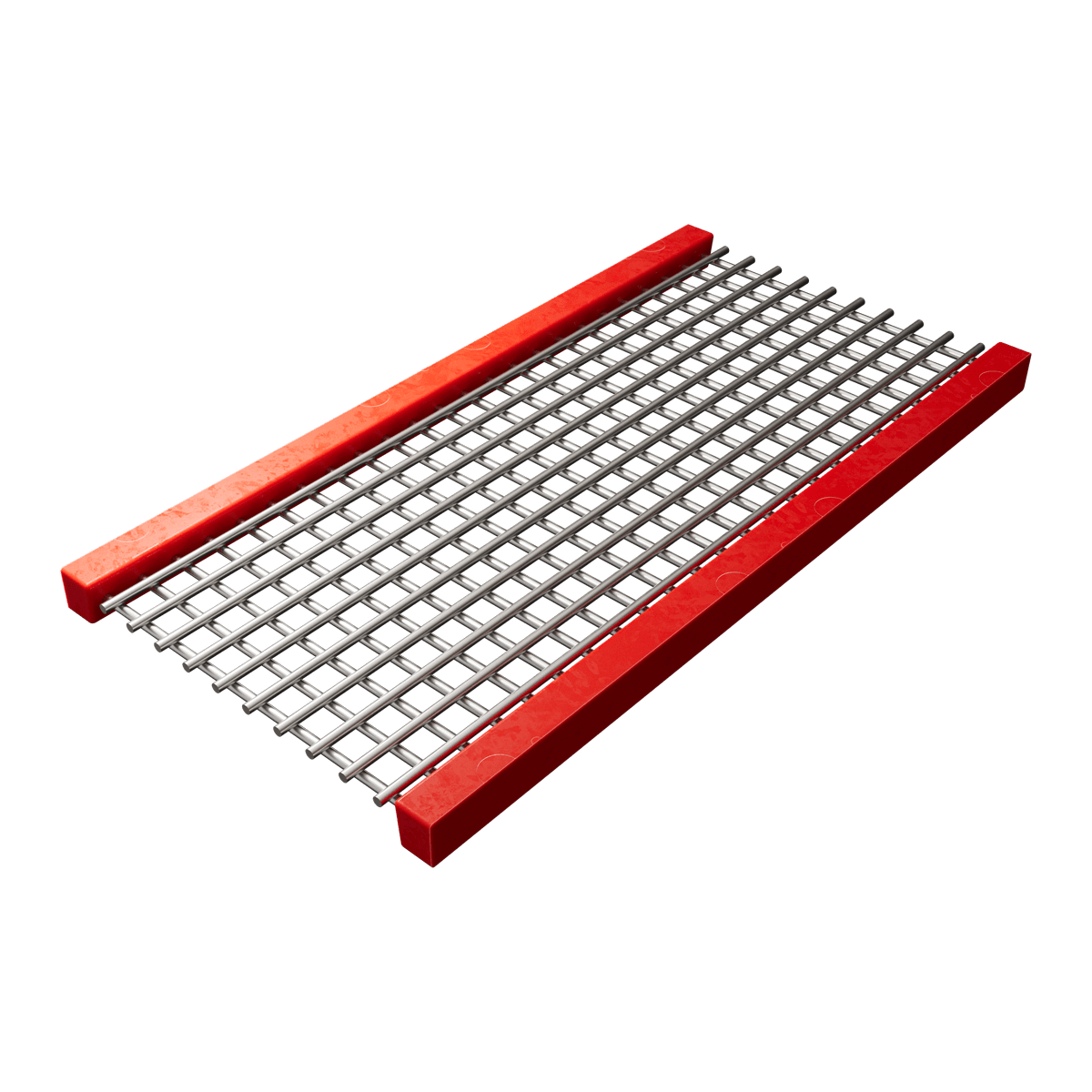

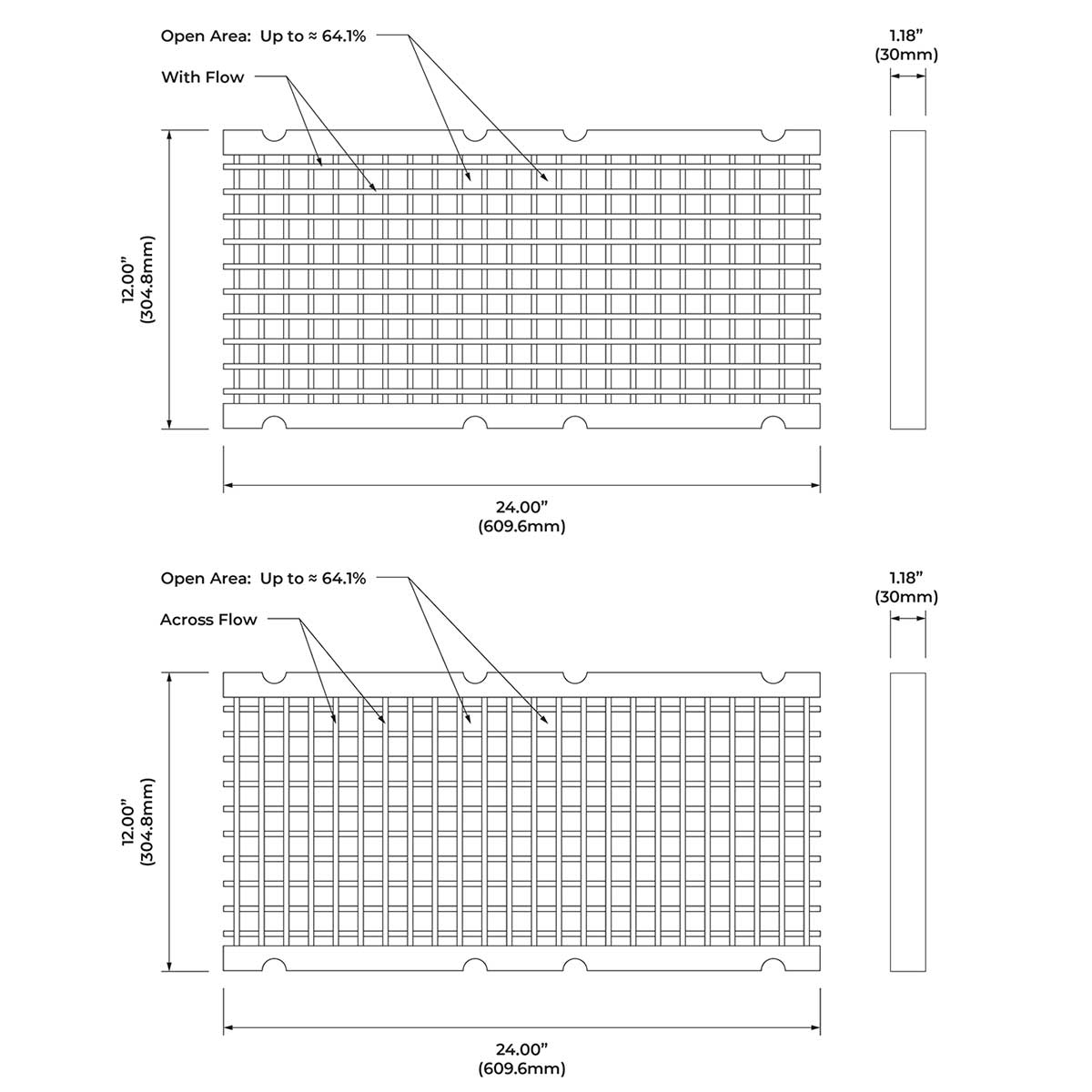

1' x 2'

Panel Thickness:

30mm, 65mm*

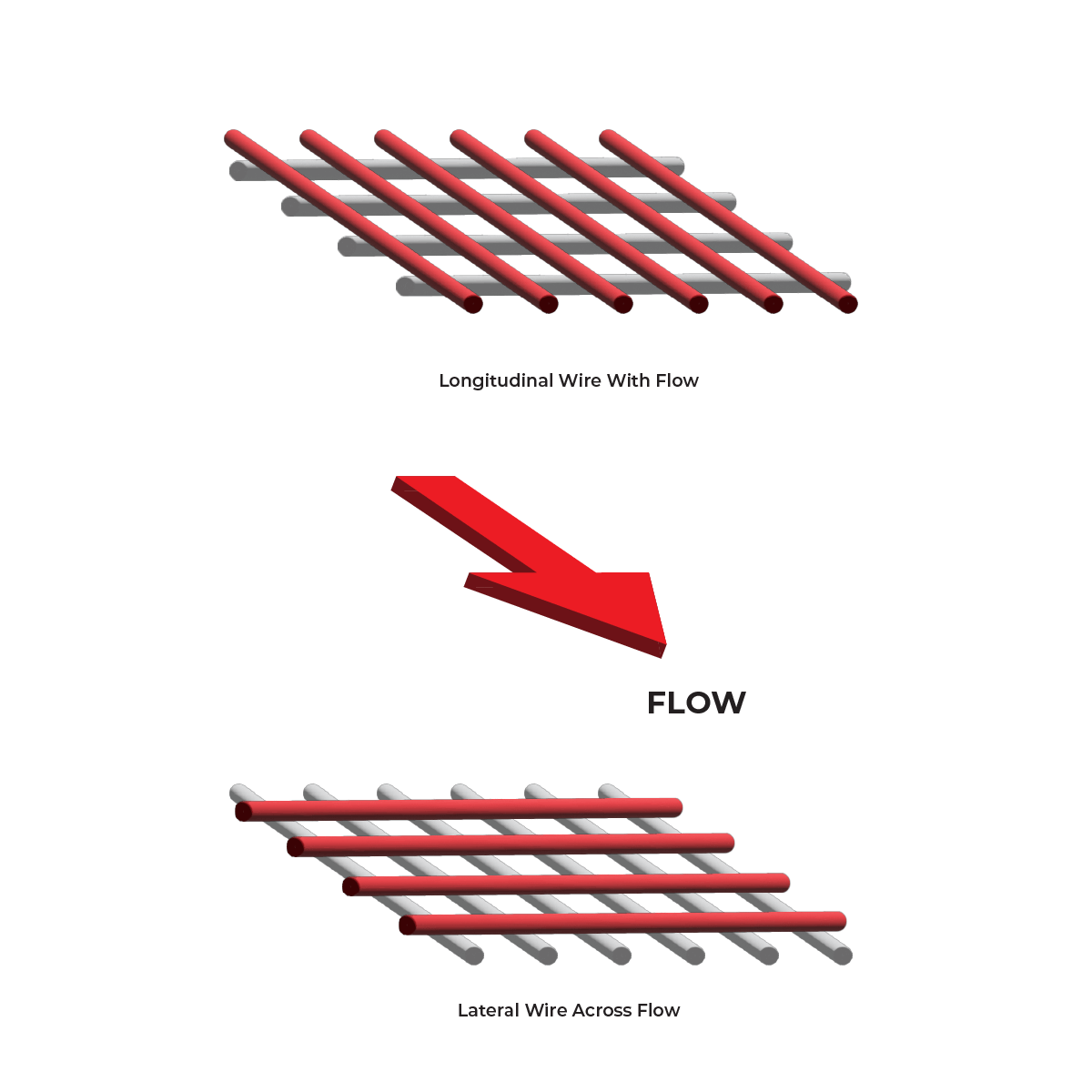

Configurations:

With Flow

Across Flow

*Available in select sizes

| Opening | Wire Diameter |

Open Area |

|---|---|---|

| 1/2” | 3/16” | 44.7% |

| 9/16” | 1/4” | 38.2% |

| 5/8” | 1/4” | 42.9% |

| 3/4” | 1/4” | 45.9% |

| 7/8” | 1/4” | 49.0% |

| 1” | 5/16” | 50.0% |

| 1-1/8” | 5/16” | 49.2% |

| 1-1/4” | 5/16” | 48.8% |

| 1-1/12” | 3/8” | 49.6% |

| 1-3/4” | 3/8” | 55.9% |

| 2” | 3/8” | 55.6% |

| 2-1/4”* | 3/8” | 59.8% |

| 2-1/2”* | 3/8” | 60.4% |

| 3” | 1/2” | 64.1% |

| *Also available in 65mm thick borders. | ||

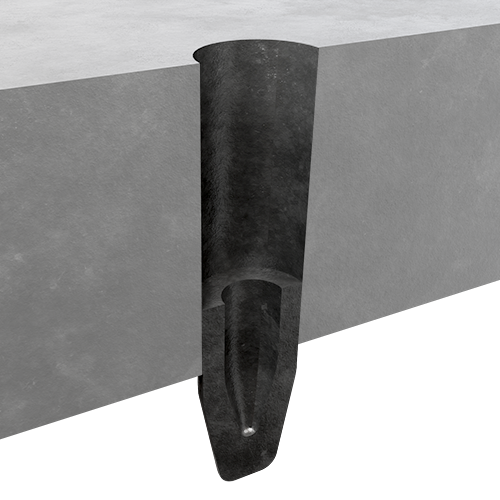

Pin

Pin

Why Operators Call METALDEX XPT a Game Changer

Open Area that Actually Works

METALDEX XPT provides open area equal to or greater than traditional wire cloth while distributing material more evenly across the deck. By exposing material to more working apertures, METALDEX XPT supports wire cloth–level throughput without the dead zones common to wire cloth.

Longer Wear Life, More Stable Performance

Built with welded wire made from 500 HBW wear-resistant steel and reinforced polyurethane borders, METALDEX XPT holds its geometry longer in abrasive applications, often delivering up to three times the wear life of traditional wire cloth.

Changeouts in Minutes, Not Hours

METALDEX XPT’s modular design allows operators to replace only worn sections, reducing maintenance time, labor, and unplanned downtime.

modular 1'x2' design for easy changeouts

wear-resistant steel

reinforced polyurethane borders

Wire Cloth vs. METALDEX XPT

Same Job, Very Different Experience

|

Category |

Wire Cloth |

METALDEX XPT |

|---|---|---|

|

Effective Open Area |

Reduced by dead zones |

Exposed across the deck |

|

Performance Over Time |

Declines |

Holds geometry |

|

Wear Life |

Baseline |

~3× longer |

|

Changeouts |

Full sheet |

Panel-by-panel |

|

Downtime |

Hours |

Minutes |

Is METALDEX XPT right for me?

METALDEX XPT is a strong fit for aggregate plant operators, maintenance leads, and production managers who are asking questions like:

- Are crowned decks limiting how much of our screening surface is actually working?

- Are we changing wire cloth more often than the wear pattern would suggest?

- Do small failures routinely force full sheet replacements?

- Would longer run cycles or faster changeouts meaningfully impact uptime?

If these sound familiar, a short conversation with one of our screening experts can help determine whether METALDEX XPT makes sense for your deck, material, and operating goals.

Frequently Asked Questions

Get clear answers to the most common questions about METALDEX XPT’s design, performance, and operational advantages.

This combination of modularity, reinforced polyurethane framing, and high-hardness welded wire forms the structural foundation behind METALDEX XPT’s durability and serviceability advantages.

Stop losing run time.

Wire cloth throughput doesn’t have to come with wire cloth changeouts. METALDEX XPT is engineered to hold onto the performance you trust, without the tradeoffs.

Backed by Polydeck’s in-house engineering team, METALDEX XPT reflects decades of screening expertise and ongoing R&D in material science and precision engineering. The result is a deck solution designed to run longer, wear more predictably, and keep production moving, even in demanding, abrasive applications.

If you’re ready to stop losing run time and start getting more out of every shift, it’s time to see what METALDEX XPT unlocks.