SUMMARY

- Twin 8×20 incline dry screens, 282-VS1 and 282-VS2, ran under the same conditions, but only 282-VS1 experienced panels popping out (panel ejections), prompting a performance evaluation.

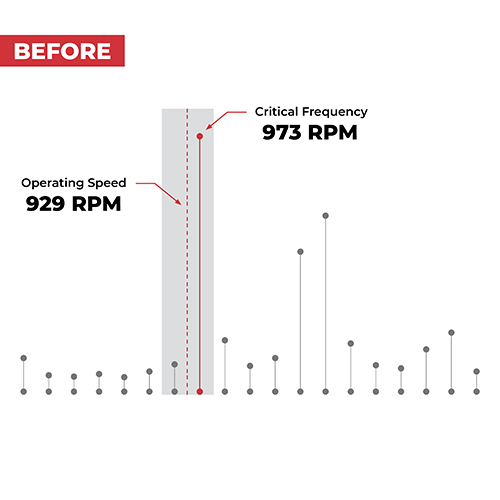

- PRO ANALYSIS testing showed that 282-VS1 was operating at 929 RPM, very close to a critical frequency at 973 RPM, creating an out-of-balance condition detectable only through vibration analysis.

- 282-VS2 served as the control, running at 919 RPM with a distant critical frequency at 1039 RPM, confirming frequency overlap—not structural issues—was driving VS1’s instability.

- Both machines showed healthy structural and side-plate deflection readings, ruling out mechanical damage.

- A motor sheave change adjusted 282-VS1’s speed away from its critical frequency, and follow-up PRO ANALYSIS confirmed stable motion and elimination of the conditions that led to panel ejections.

When Hidden Resonance Mimics Mechanical Failure

In many aggregate operations, screen performance issues—such as panels popping out, uneven travel, or inconsistent motion—are often assumed to be mechanical problems. But one of the most overlooked causes of instability is critical frequency overlap, where a screen’s operating speed sits too close to one of its natural frequencies.

This type of resonance doesn’t always produce obvious signs. A machine can look completely normal during production, yet subtle vibration changes can undermine panel retention. These hidden motion changes can directly contribute to unexpected panel ejections, even when a screen appears mechanically sound.

This case highlights how resonance created a panel-retention issue on one machine—while its twin, running just a few RPM slower, performed flawlessly.

The Challenge: One Twin Screen With Panel Ejections, One Running Smoothly

The site operated two twin 8×20 incline dry screens—282-VS1 and 282-VS2—under similar feed conditions and with the same deck configuration. Yet only 282-VS1 was experiencing panels popping out.

To operators, both machines appeared to run normally. There were no visible signs of twist, excessive vibration, or mechanical fatigue. Both screens shared comparable structures, stringers, and media layouts, leaving no obvious reason for the difference in behavior.

Still, panels popping out on 282-VS1 signaled that something deeper was affecting its motion stability—while 282-VS2 continued to operate reliably without any retention issues.

The plant needed to understand why two identical machines were producing such different outcomes.

Experiencing Panel Ejections

Stable Operations

The Diagnostic Breakthrough: Motion Testing Exposes a Critical Difference Between the Twins

With no visible signs of structural issues and both screens appearing mechanically sound, a PRO ANALYSIS diagnostic was conducted to understand what was driving the panel instability on 282-VS1. The evaluation included orbit measurements, side-plate deflection checks, structural deflection analysis, and—most importantly—critical frequency bump testing.

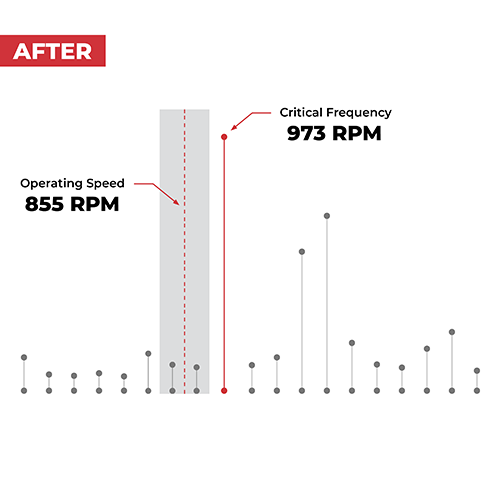

Orbit Findings

- 282-VS1 showed an unbalanced orbit pattern, with uneven displacement between the left and right sides. This imbalance was subtle and not visible to the naked eye, but clear in the recorded data.

- 282-VS2 produced a clean, centered elliptical orbit, indicating balanced, stable motion.

Critical Frequency Findings

282-VS1 (the problem screen)

- Operating speed: 929 RPM

- Critical frequency: 973 RPM

- Separation of only 44 RPM, placing the machine dangerously close to resonance

- Result: Operating too close to resonance, creating subtle motion instability

282-VS2 (the healthy control screen)

- Operating speed: 919 RPM

- Critical frequency: 1039 RPM

- Separation of 120 RPM, creating a wide and safe buffer from resonance

- Result: Ideal separation from resonance, driving stable performance

Structural & Side-Plate Deflection

Both screens showed competent deflection readings, confirming:

- No structural weakness

- No side-plate instability

- No mechanical damage contributing to the issue

Breakthrough Insight

The contrasting vibration behavior made the root cause unmistakable:

critical frequency proximity—not structural issues—was destabilizing 282-VS1 and contributing to panels popping out.

The Solution: Adjusting Operating Speed Through a Sheave Change

With resonance confirmed as the driver of motion instability, the operation implemented a motor sheave change to give 282-VS1 additional separation from its critical frequency.

What is a sheave change?

A sheave is a pulley used in the drive system to transfer power from the motor to the vibrating screen. The relationship between the motor sheave (driving sheave) and the screen shaft sheave (driven sheave) determines the screen’s operating speed.

In many applications, speed adjustments are made by changing the motor sheave, not the screen’s sheave. Motor sheaves are smaller, more readily available, and less costly to change, making them the preferred adjustment point in the field.

Because the sheave change is made on the driving side of the system:

- Installing a larger motor sheave increases screen speed

- Installing a smaller motor sheave reduces screen speed

By adjusting the motor sheave on 282-VS1, the operating speed was reduced from 929 RPM to 855 RPM, creating a safe buffer from the critical frequency at 973 RPM and eliminating the resonance condition that was destabilizing the machine.

The Results: Balanced Motion, No Panel Ejections, and Reduced Maintenance Burden

A follow-up PRO ANALYSIS diagnostic confirmed that the sheave adjustment successfully resolved the issue. With 282-VS1’s running speed moved safely away from its critical frequency, the machine’s motion profile returned to stable, predictable performance.

Key outcomes included:

- Clean, balanced elliptical orbit patterns, matching those of 282-VS2

- Even left-to-right displacement, with no signs of resonance-induced amplification

- Complete elimination of the instability that previously caused panels to pop out

- Reduced maintenance downtime, as operators no longer needed to reset or replace loose panels

- Fewer resources spent on reactive maintenance, enabling the team to focus on proactive tasks

- Consistent performance between the twin screens, restoring reliability and confidence in the circuit

By resolving the resonance issue at its source, the site regained operational stability without structural repairs, component replacement, or additional capital investment—demonstrating how a precise speed adjustment can resolve problems that are otherwise invisible during routine operation.

Why It Worked

The instability originated from 282-VS1 operating too close to one of its natural frequencies, which amplified stroke behavior in subtle ways that reduced panel retention. These changes were not noticeable by eye but had a direct impact on how securely the panels seated during operation.

By reducing the running speed through a sheave change:

- The screen moved safely away from resonance

- Harmonic amplification disappeared

- Motion returned to centered, balanced patterns

- Displacement equalized

- The conditions that had been causing panels to pop out were fully corrected

This is a clear example of how data-driven diagnostics uncover root causes that are invisible during routine operation.

Frequently Asked Question

Why are my screen panels popping out even when the machine looks like it’s running normally?

Panels popping out are often caused by subtle motion instability that isn’t visible during routine operation. When a vibrating screen operates too close to a critical frequency, resonance can alter stroke behavior just enough to affect how securely panels seat and retain—even if the machine appears balanced to the eye.

Over time, operating near a critical frequency can also contribute to fatigue in structural components such as cross members, diagonal supports, and stringers. This localized flexibility can create erratic motion at fastening points, further exacerbating panel retention issues.