Polydeck has long been innovators in the world of modular media and continue to be a pioneer in the screen media space as a company focused on creating a more sustainable future. Recognizing the importance of balancing environmental, social, and economic factors with growth, Polydeck has incorporated a sustainability mindset throughout every aspect of its operations. By focusing on creating a better world for future generations, Polydeck's comprehensive approach to sustainability has resulted in numerous environmental and social benefits for the company, its employees, and its customers.

Zero-Waste-to-Landfill: A Success Story

Polydeck's sustainability initiatives began with a targeted effort on repurposing waste material to divert it from landfills. Through recycling, cleaning, and recovering excess materials, Polydeck has managed to redirect over 90% of its waste away from landfills while also incorporating a percentage of recovered material into auxiliary products. As a result, Polydeck is providing benefits to both the environment and its customers through the cost savings generated by their efforts.

Responsible Sourcing: A Commitment to Ethical and Sustainable Practices

Polydeck's dedication to sustainability is further evident in its responsible sourcing practices. The company has forged strong partnerships with suppliers who share its commitment to ethical and sustainable practices. Polydeck is dedicated to working with suppliers that uphold the highest standards in labor, ethics, environmental responsibility, and human rights. By prioritizing responsible sourcing, Polydeck can provide environmentally friendly and socially responsible products to its customers, reinforcing the importance of sustainability throughout the entire supply chain.

Community Engagement: A Pillar of Social Responsibility

Polydeck understands that a commitment to sustainability extends beyond its own operations and reaches into the local community. The company actively supports local organizations and initiatives that promote education and social responsibility. For example, Polydeck partners with local schools and non-profits to provide education, food, clothing, and other wellness needs to help people create a better future for themselves.

Employee Development: The Key to Driving Sustainability

Investing in employee growth and development is a cornerstone of Polydeck's sustainability strategy. The company's training and development program empowers its employees to make well informed business and personal decisions while creating a safe and productive work environment. Polydeck’s training program includes coaching, leadership training, skills training, and other professional development opportunities to help team members grow and succeed within the company and their personal lives.

Polydeck's Ongoing Commitment to Sustainability

Polydeck's sustainability journey is an ongoing effort that started through the continuous improvement efforts engrained in the company’s culture and core values of Caring, Excellence, Integrity, and Humility. Polydeck is committed to helping create a more sustainable future to serve their customers and stakeholders with excellence and conduct business in a way that cares for people and honors God. When you choose to partner with Polydeck, you choose a company that stands for a greener, more responsible future. Upgrade sustainably. Upgrade with Polydeck.

From the outside, Polydeck may just seem like a company focused on delivering innovative, high-performance solutions. However, beneath the surface, we are a team of superheroes providing world-class quality, service, and support to our customers. Together strong, our team of superheroes understand the specific challenges you face and how to help you overcome them to achieve maximum performance.

We’re ready to save the day

Most of our outside team have been in your shoes, so not only do they know what you need, but they also understand the frequency of empty promises you may have received. At Polydeck, we say what we will do, and then we do it. We are committed to you and your operation’s success.

We have secret weapons

The Polydeck team has key strategies in place to ensure victory for your performance. Our superheroes can piece together the whole picture to get you what you need, right when you need it. They can access our distribution centers and unlock specific inventory to deliver to you in a pinch. They can track orders and offer other bits of critical information, such as when cranes or crews are scheduled. The multitude of what our team of superheroes can do to serve you are endless.

We can do this all day

They might not be as well-known and tough as Captain America, but our team is constantly doing whatever possible to achieve a win for you: from training new staff on panel changeouts, delivering panels in order to avoid freight delays, or to taking the time to give your crew a complete system overview before the work begins.

We can adapt to anything

Our people know screens and media, so it doesn’t matter what media type or brand of screen you currently have installed. Our team of experts can still come in to inspect and survey your process to help you troubleshoot and improve performance.

We’re your super-friends!

You can call on us for anything. Need something on an impossible timeline? We have a Polydeck superhero for that. Need to exceed your current production rates? We’ve got a superhero for that, too. Our super team will work around the clock and give every effort to help you achieve your goals.

In the Aggregate and Mining Industries, high volumes of rock and ore are produced and processed each day. It is critical to know the exact sizes of the rock in each product or process stage for the following reasons:

- The salable products typically need to meet State or Federal Specification requirements, and

- Process specifications help optimize the efficiency of commodity recovery and reduce downtime in the plant.

However, counting and measuring each stone or particle by hand is not a scalable solution for the size of these operations, so these industries depend on using Sieve, or Gradation, Analyses to determine the average material sizes of the overall product by periodically sampling the larger process stream.

Terms and Standards Used in Sieve Analysis

Before getting started, it is important to define some of the key terms and standards used when conducting a sieve analysis. These terms are not used in common vernacular and are critical to the steps and processes that follow.

Key Terms

- Gradation: The particle size distribution of an aggregate.

- Sieve: A device used for separating the sample by particle size.

- Fraction: The portion of the sample retained on each sieve.

- Shaker: An instrument to mechanically separate particles by size.

- Percent Retained: The percentage of material retained above each sieve size.

- Percent Passing: Percentage of total material that passed through each sieve.

Identifying industry standards

ASTM International, previously American Society for Testing and Materials, is an international organization that produces technical standards. Using Industry Standards ensures that the test will be conducted uniformly between plants, which yields a level baseline of products between each unique site conducting the test. Below are two standards that may be used as resources for sample reduction and conducting Sieve Analyses, which include guidelines and tips on each process.

- ASTM C136: Standard test method for Sieve Analysis of fine and coarse aggregates

- ASTM C702: Standard practice for reducing samples of aggregate to testing size

Preparing for the Test

Step 1:

The first step in conducting a successful Sieve Analysis is starting with a well collected, dry sample.

If the sample is wet, the material will not flow freely or separate properly. Thus, it is important to dry the sample in an oven with a temperature ≤110°C. Dry times vary by material type, sample size, moisture content, and oven efficiency, so check the sample intermittently until it is dry and free flowing.

Step 2:

After a sample has been dried, a preliminary weight is needed. With the pan in place, tare the scale; if the scale does not have a tare option, the pan will need to be weighed separately to be subtracted from the sample weight.

Using a splitter, separate the sample to the appropriate size. If a splitter is not available, use the cone method to split the sample: Pour the sample into a conical shape and divide the sample into four quarters. Once sectioned, add the sample to the tarred pan to collect a preliminary total material weight.

After the preliminary weight is recorded, the entire sample will be transferred to the top tier of a sieve shaker.

Step 3:

Close the sieve stack and assemble the stack onto the shaker, if applicable, making sure that it is centered on the base and completely nested under the top cover before tightening. Lock/tighten the stack in place. Power on the shaker and set the time.

Conducting the Test: Cumulative Method

The most common method of conducting a sieve analysis is the cumulative method.

Step 1:

Start by removing the top tray and transferring the fraction into the tared pan on the scale. Record the weight of the fraction.

Leaving the material in the weigh pan, repeat the process by removing each subsequent tray and recording the total weight after adding each additional fraction to the weigh pan.

Once each fraction is added and the weights are recorded, compare the final total weight to the preliminary total weight; check for a difference less than or equal to 0.3%.

If the difference is greater than 0.3%, the test will need to be repeated with a new sample.

Step 2:

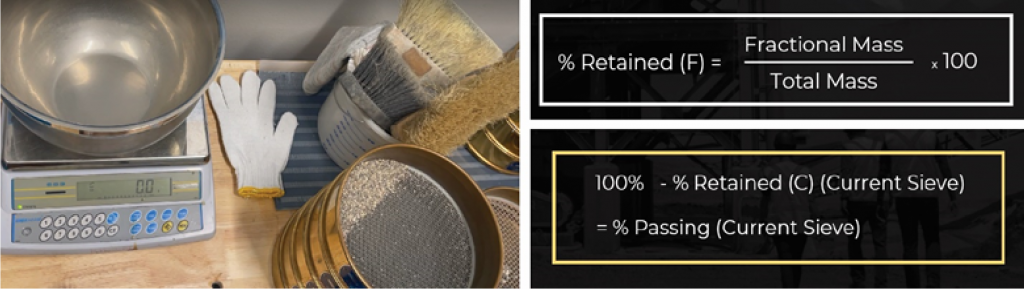

Calculate the cumulative percent retained for each line by dividing each cumulative gradational weight, as recorded from the test, by the total weight of the sample, and multiplying by 100%.

As an example, 12.6 grams of mass retained would be divided by the total weight of 309 grams to yield a calculation of 4.0% retained.

Step 3:

To calculate the cumulative percent passing, subtract the percent retained values for each line from 100%.

Continuing with the previous example, subtracting 4.0% retained from 100% yields a 96% passing product.

Conducting the Test: Fractional Method

Unlike the cumulative method, the fractional method for conducting a sieve analysis will measure and record each fraction individually. This occurs by emptying the tare pan between each weight. Other than this major difference, the fractional method is very similar to the cumulative method.

Step 1:

Weigh the material in each sieve individually and record the mass; tare the scale before each fraction weight.

Step 2:

Calculate the fractional percent retained for each line by dividing each fractional gradational weight, as recorded from the test, by the total weight of the sample, and multiplying by 100%.

Step 3:

Calculate the percent passing by subtracting the fractional percent retained, along with the fractional percentages retained for all sieves larger than the one under calculation, from 100%

As an example, with a 21.3% retained calculation, 21.3% needs to first be subtracted from 100%. Then, also subtract the fractional percentages that were retained above it. In the example above, that includes 27%, 25.8%, and 4%, which indicate a 21.9% passing.

Helpful Tips for Conducting a Sieve Analysis

When conducting a Sieve Analysis, unexpected events can occur during the process that may need to be addressed and/or accounted for. Download our list of recommendations and mitigation techniques which can aid in successful completion of the analysis.

This blog was adapted from a 2021 educational webinar with Polydeck experts, Craig Burke, director of Engineering, and Jamie Mills, New Product Development Application Engineer. To learn more about upcoming educational opportunities, subscribe to our newsletter.

Polydeck Screen Corporation, the leader in injection molded screen media for the mining industry, is pleased to announce the grand opening of its highly anticipated manufacturing expansion on October 31, 2022, at its Spartanburg, South Carolina headquarters.

The company purchased an additional building with over 36,000 square feet next to its current campus that will help increase capacity and keep up with current and expected future demand. Along with the additional square footage, the company is also proud to announce that this expansion will bring 35 new jobs to the local area.

“This move signifies the continued growth our company has experienced from customer demand,” states Todd Nalepka, Senior Director of Manufacturing. “Outgrowing our current manufacturing model required us to expand the factory footprint – which has been an exciting challenge for the team. It enabled team members to think creatively and strategically with how to best position our collective production system for the future. After evaluating several options, we found that relocating our Rubber Department to a new building would be most optimal. This expansion unlocks growth opportunities for other departments, increases efficiency, and improves safety across the board,” continues Nalepka.

On November 1, 2022, phase one started with the Polydeck Rubber Department moving to the new space. By March 2023, phase one of the project should be complete in order for more departmental shifts and growth opportunities to begin.

Ron Kuehl, President at Polydeck says, “It’s been a special time for Polydeck. With several moving parts, this expansion has required multiple internal teams to work together through effective communication, planning, and scheduling to pull the move off well. Through the commendable efforts and teamwork of these different departments, we project an estimated 7+ years of sustainable growth to accompany the move.”

As a result of the move, multiple departments across several buildings will be reconfigured to allow space for new manufacturing machines needed to meet the projected demand. These changes will increase efficiencies throughout the production process and enable Polydeck to be positioned to maintain its industry leading lead times by controlling material flow through the plant.

The Polydeck culture is centered around a holistic view of partnering with our customers to meet their needs. Our company mantra, Together Strong, illustrates a commitment that goes far beyond providing high-quality products. While we are proud of the products we offer, we find it more fulfilling to come alongside our customers and troubleshoot the issues they face by assisting with installations and minimizing their downtime by providing the most competitive lead times in the industry.

The way we can provide short lead times is through our distribution center network and supply chain management. With seven distribution centers located strategically across the United States and Latin America, we can meet demand in a matter of hours, or days, to get our customers the products they need when they need them.

How Our Distribution Centers Work

Our distribution centers work together with Polydeck manufacturing sites in Spartanburg, SC and Santiago, Chile to maintain the right combination of products our customers need. With hundreds of products in stock, including accessories, stringers, and screen media, we pride ourselves on strategic inventory planning to ensure we can cover our customers’ needs as they arise.

In tandem with our manufacturing sites, distribution center managers continuously evaluate inventory levels and product mix based on demand. Keeping a pulse on customer need, managers can adjust inventory and stock items to quickly respond to emergencies or shifts in demand.

Providing Value Beyond Lead Times

While distribution center managers work alongside customers to maintain their screen media or other Polydeck product needs, the value goes well beyond short lead times. Additionally, Polydeck has an extensive network of Application Experts located across North and South America who are trained with the knowledge and tools to help troubleshoot any part of the screening process.

Having distribution center managers and application experts regularly on-site offers Polydeck customers the additional security of knowing their screens are being consistently inspected to ensure that everything is running at maximum efficiency and delivering the best results.

As customers expand their operations and add new screen decks, consistent communication with Polydeck helps proactively anticipate product needs and the ability to plan stock levels as needed.

Our Commitment to Customers

Polydeck distribution centers allow us to provide quality products with short lead times. But the value Polydeck brings to our customers is in our commitment to partnering together to solve problems. We genuinely believe that together we are better. Together we are strong. Together Strong!

Written by Armando Cardenas, Polydeck Distribution Center Manager in Tucson, Arizona.

On June 7, 2022, Polydeck celebrated the sponsorship of its first Habitat for Humanity home being built in the local Spartanburg community with a traditional wall-raising ceremony. This event marked the first of several homes that Polydeck has lined up to build over the next few months through the Habitat for Humanity organization.

Prior to the ceremonial wall-raising, several speakers including Polydeck’s CEO, Peter Freissle, Polydeck’s President, Ron Kuehl and the recipient of the home who would like to be known as Ms. Martin, took to the stage to share blessings and goodwill for all that this home will represent. For the Polydeck team, this home embodies the company’s commitment to social responsibility and the heart of the Freissle family which is to care for those in need. For the Martins, this home represents a long-awaited dream finally coming true- home ownership, and the hope that this home will be a blessing to generations of Martins to come. Before the crowd scattered and the Polydeck crew got to work on building the home, each attendee signed words of encouragement on the house’s wood structure to remember the significance of this partnership.

“Polydeck is a company founded on Christian values that prioritizes giving back locally, nationally, and globally,” states Polydeck’s Human Resources Director, Linda Coltrane, “It brings us tremendous joy to partner with an organization like Habitat for Humanity, to formulate a new connection with the Martin family, and to provide an incredible opportunity for our employees to serve together in a hands-on way to impact the Spartanburg community.”

With construction having begun immediately following the ceremony, the approximately 1,100 ft2 home will be ready for Ms. Martin to occupy in just a few short months. In the meantime, Polydeck will celebrate two more wall-raisings in the neighborhood so that several others may join Ms. Martin in receiving a new home.

The historic rush for gold that erupted in 1849 in the state of California, later jumping to Canada’s Yukon Territory, was less about striking it rich and more about daring to take chances—trying and failing, and trying again. American entrepreneurship shifted into high gear in those days. Fast forward to the present: Discovery Channel’s television series Gold Rush has hit the mother lode for six seasons, ranking as the top-rated show on the network.

Dave Turin, a principal cast member of the TV series ‘Gold Rush,’ checks a feed box at the Klondike gold operation. (Photo: Gold Rush)

Dave Turin, a key character on the show, described the series as the saga of down-on-their-luck construction workers facing all odds in the hopes of making good in the gold business. “It speaks to ‘the American spirit,’ that of taking a chance—and getting off the couch, putting your boots on, and getting to work no matter what the risk,” he said. Turin is teamed up with cast member Todd Hoffman, the founder and leader of 316 Mining, which operates on a claim in the Klondike region of the Yukon in northwestern Canada.

“These haven’t been easy chances, as we weren’t very successful in the first several seasons— but we’ve stayed at it and we’ve evolved as does any start-up business,” said Turin. As to the current season, he said, “We’re catching a lot of gold.”

The successful evolution of the Gold Rush mining teams is due in part to the expertise and equipment provided by a number of the nation’s top mining equipment manufacturers. Among them is Polydeck. The company first got involved with Gold Rush in 2012 when providing the screen media, a frame system, and accessories for the top deck of a 5 x 16-ft double-deck vibrating screen.

During the current Gold Rush season, Polydeck conducted a complete screen performance evaluation for the 316 Mining team. These “value-added” evaluations, according to the company, often lead to greater screening efficiency by determining needed adjustments to screen speed, stroke and acceleration. The latter is combined with an analysis of the support structure, bearings, and other key components to help prevent excessive wear and potential equipment failures.

Polydeck said it takes a unique bigger-picture approach to maximizing screen performance for its customers. At the 316 Mining site, the screen performance evaluation and subsequent fine tuning ultimately led to an estimated 25% increase in overall screening efficiency for the Hoffman/Turin crew.

“Working with Polydeck is a great partnership. They continue to take chances on us—and that’s what our show is all about,” said Turin, who added that he first requested Polydeck screen media several seasons ago. “Back then, we put their media on the top deck of the wash plant that we called ‘Big Red.’ This season, we’ve got it on the plant we call ‘Monster Red,’ and we’ve doubled the production capacities that we had two years ago.”

Turin became familiar with Polydeck media when he installed it in his family-owned quarry and paving business, which is based in Oregon. “It’s all about the longevity of the Polydeck media. Unlike traditional wire cloth, we can put Polydeck in, and forget about it. The money we save in labor and wire cloth changeouts far outweighs the initial cost of the media. That’s why we wanted it for our gold mining operation.”

Targeted Solutions

In 2014, the Hoffman/Turin crew upgraded to a larger triple-deck, 6 x 20-ft screen, and once again requested Polydeck media. Turin shared their specific requirements with the Polydeck engineers, who recommend the optimum configurations of opening types and sizes for the application. “They understand our machine; what we are sluicing; and provided us the just the right openings for our type of material,” said Turin.

Polydeck provided both Polydex modular polyurethane panels and Rubberdex modular rubber panels—as well as frame systems and side wear plates. Turin said the modularity of the deck means they can change out a single panel at a time if need be; rather than replace the entire deck. The biggest thing, he said, is being able to change out panels as necessary on just the feed end where you get all the impact and wear.

Polydeck’s new Armadex bolt-down rubber chute panels are installed on the feed end of the top deck. Armadex sections are steel-backed rubber panels that combine a proprietary blend of natural gum rubber with a high-strength/low-alloy steel plate backing, making it ideal for tough, abrasive applications. According to Polydeck engineers, Armadex panels are created using a Binary Injection Molding (BIM) technology, which is a proprietary Polydeck manufacturing method that produces 10 times the pressure normally used to produce compression-molded rubber. Poydeck said combining this process with premium natural gum rubber and HS/LA steel plate backing produces unprecedented strength, which results in longer wear life at lower costs per ton.

Hoffman said, “We’ve got the best wash plant in the Klondike, hands down.” His crew reported that over two seasons, they have put more than 800,000 yd3 of abrasive, quartz-filled material over the rubber and polyurethane decks, at an average of 250 yd3/h—running 24/7 from June through September each season. “The decks still look great and we’ve maximized our uptime and saved big bucks on maintenance and labor. For example, if we had used standard AR Steel plate on our feed end (vs. the Armadex), we would have been changing that out once a week,” said Turin.

Turin and Todd Hoffman (right), another cast member, say they are convinced the initial cost of installing polyurethane and rubber media panels and parts is significantly offset by reduced labor requirements and longer service life provided by the Polydeck products.

Big-picture Performance

Mike Garrison, a Polydeck product support specialist, has conducted hundreds of screen performance evaluations in the mining industry. He traveled twice to the Yukon to visit the 316 Mining site to complete an evaluation and offer solutions for greater efficiency. “We offer the technical assistance that goes beyond looking at screen media and examines the entire screening circuit—to make the circuit more reliable, to increase their recovery; and to minimize maintenance,” said Garrison.

Evaluations record a screen’s orbits; motor speed; any harmful deflections along the Z axis; material travel rates; and any movement of the support structure. It also examines a screen’s critical frequencies to help determine the screen’s optimal speed and stroke. Importantly, the final report includes any recommended adjustments to a screen’s operating parameters and/or media to maximize its operating potential in its particular application.

Within Garrison’s detailed report, an example of one of the major issues uncovered during the evaluation is that the combination of the screen’s displacement and acceleration was excessive for the bottom-deck apertures (openings) and was likely contributing to inefficient screening on the bottom deck. The level of acceleration was also causing body (Z) axis deflections along the bottom deck. Consequently, adjustments were made resulting in an 11% reduction in the displacement (stroke) of the vibrating screen. “This adjust ment boosted overall recovery and had an immediate effect upon overall efficiency,” said Garrison.

After fine-tuning the screen’s operating parameters, Turin reported that they saw a noticeable improvement in the bed depth and carryover on the bottom deck. “We have increased production to 280 yards per hour with very little carry over. Depending upon the quality of pay dirt that we run, our recovery rate is between 3/4- and 1-1/2-ounces for every hundred yards of material over the screen, which is a significant increase over last season,” said Turin. While initially skeptical of all the troubleshooting, Turin said the results achieved after completing the recommended adjustments has him convinced of the value of conducting periodic screen performance evaluations.

Science and Synergy

Optimum screening performance is less about trial and error, and more about understanding the science of screening. The Hoffman/Turin crew acknowledged that its partnership with Polydeck has allowed them to “dial in” their requirements; and continually identify areas that will deliver the greatest return. Ultimately, it’s all about less risk and greater recovery.

Written by Carol Wasson, veteran freelance writer for the aggregate and construction equipment industries.

Polydeck’s safety culture is based upon our core value of caring for people. We believe that striving for safety excellence is the single best way we honor and care for our team members so that they return unharmed to their loved ones each day. By ensuring that we act safely and by going out of our way to provide a safe and healthy work environment, we hope to accomplish our goal of being a world class safety organization grounded in the idea that acting safely is how we care.

Every team leader and member at Polydeck uses safety excellence as a compass rather than a lofty target. This can be a daunting objective because ensuring the entire workforce operates with a “safety always” philosophy is more of a mindset than a tag line. And, as we all know, changing and evolving a mindset is not easy. Mindset alone cannot achieve safety excellence, but it certainly impacts behaviors. Behaviors that produce positive and safe habits directly correlate to lowered workplace incidents. Therefore, we are confident that an engaged team of people who live with a “safety always” mindset is the start to a safe organization.

When team members truly buy-in and care deeply for those around them, significant changes occur. Recall great teams that have won championships, or groups of people who have affected policy changes, or creatives and inventors who have impacted technological fields with life-enhancing and life-saving solutions—these circumstances required dedicated people with a committed passion for the work being done. They did it for themselves and for others, and they were met with amazing results. This is how we feel about safety. Sure, we can attempt to lean on policies, OSHA regulations, or even automated equipment to make our site safer, but those elements will only get us so far. That is why in addition to our safety slogans, vision statements and policies, we have simplified safety excellence to the idea that we need to work together to care for each other.

At Polydeck, we have seen team members lead by example and go above and beyond safety expectations because the ownership that they recognize without ambiguous “rules,” empowers and enables them to act whenever safety is compromised. Team members are motivated to catch safety hazards and recommend improvements to help one another create a safer workplace environment. This sense of purpose is the heartbeat of our safety culture.

With each individual working together, we strongly believe that we will accomplish world-class safety. Together Safe. Together Strong.

Written by Todd Nalepka, Director of Manufacturing at Polydeck.

Ryan Johnson, director of R&D, and Trey Rollins, director of marketing, speak about the solutions Polydeck is creating to monitor screen media panel health.

“Our research has led us to focus on three primary concerns operators have in relation to the reliability and availability of their screen media,” Johnson explains.

“The first concern revolves around the reliability of screen panel fastenings. Operators need to be confident all screen media panels are securely fastened during installation and remain fastened during operation. Displaced screen panels can block material flow, send misplaced material through the process, and potentially damage equipment. Our technology ensures an operator can detect fastening issues before a panel becomes displaced and alerts an operator so that action can be taken quickly to prevent contaminated product piles.

“The second concern centers around screen availability in relationship to media performance and wear life. The media health technology designed into our panels will help operators more precisely understand the wear life of a screen panel and be able to plan maintenance activities based on the predicted life of panels in service. The ability to measure panel wear life in real time creates an opportunity to optimize screen media selection by location on the deck, and develop media maintenance plans that balance cost and performance. The ability to detect specific panel location gives an operator insight into specific wear patterns and opportunities to drive efficiencies throughout their process.

“Third, our concerns center around screen media being installed in the proper location on a screen deck. Due to screen decks often having two or three different aperture-sized panels on a deck, operators need to be confident that all media panels are placed in their proper location. The correct placement of the media ensures an operator is set up to achieve their target separations and maximize efficiencies.” Today, media panel wear is managed through manual tracking processes and visual inspections. Product gradations taken after material is screened also provide an indirect measure of panel condition but serve as a lagging indicator of the wear a panel has experienced. In reality, screen decks are often difficult to access, and visibility of the panels is minimal, particularly on lower decks. Moreover, a thorough inspection of a screen wear requires both a machine shutdown and a dedicated person to perform inspections and take measurements, making visual inspections expensive and time consuming. Typically, the best information an operator has at their disposal is a historical record of service intervals and changes made to a screen. The advent of “smart panels” i.e., those embedded with sensors to help operators monitor, manage, and measure the performance and wear life of their screen media in real time via the Industrial Internet of Things (IIOT), could prove a useful alternative.

There are two different types of critical information that smart panels could provide.

First, information on tracking long-term usage and performance patterns of the screen media. Data used for this could include the age of the panel, the wear life and the physical location. The goal is to use this data to build predictions of wear life, and in turn, predict when maintenance might need to be performed or replacement parts ordered. This information can be used to optimize maintenance planning, avoid stock-outs, and ensure the most efficient use of screen media.

Second, detection of critical events that may require an urgent response. For instance, the dislocation of a screen panel or an impact that breaks or punctures the screen media. Today, if a panel comes loose or fails catastrophically, operators often don’t know until it’s too late. Using embedded sensors to connect operators with the screen panels could help users avoid costly downtime and repairs and reduce the chance for misplaced material within a circuit.

“We believe that integrating digital technology into media panels will be a key part of screen management practices in the future and will help further increase efficiencies throughout the material processing process,” states Rollins.