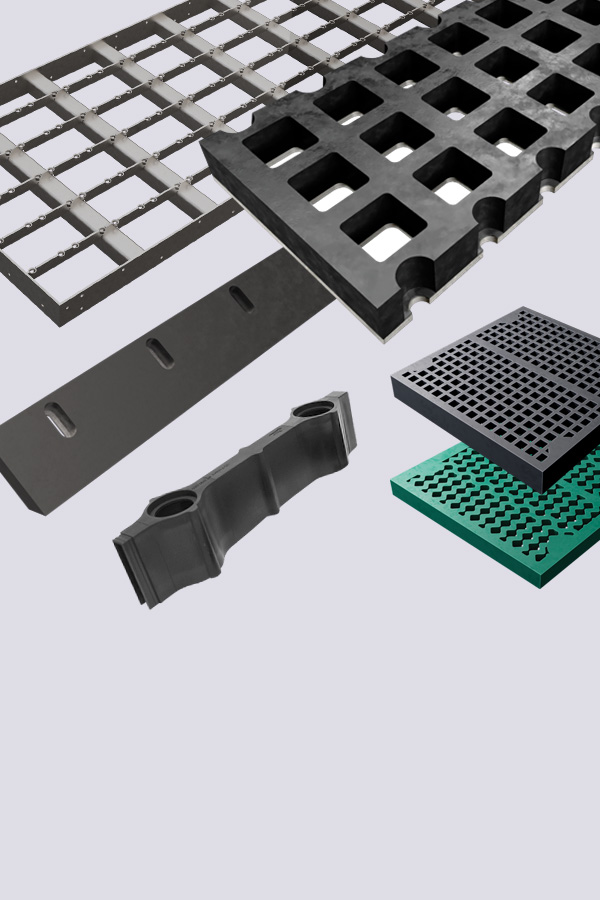

CONVEYOR BELT LINERS

Move material with confidence.

Material spillage and dust on conveyors can disrupt operations and require frequent clean-up. PROTEX CBL conveyor belt liners are engineered to adapt to your operation’s conveyor belt sides, providing precise fit and heavy-duty durability. Ensure stable control of bulk-loaded material and reduce spillage.

Extend wear life of conveyor sides.

Reduce conveyor maintenance costs and downtime.

Stabilize bulk-loaded material and prevent material loss.

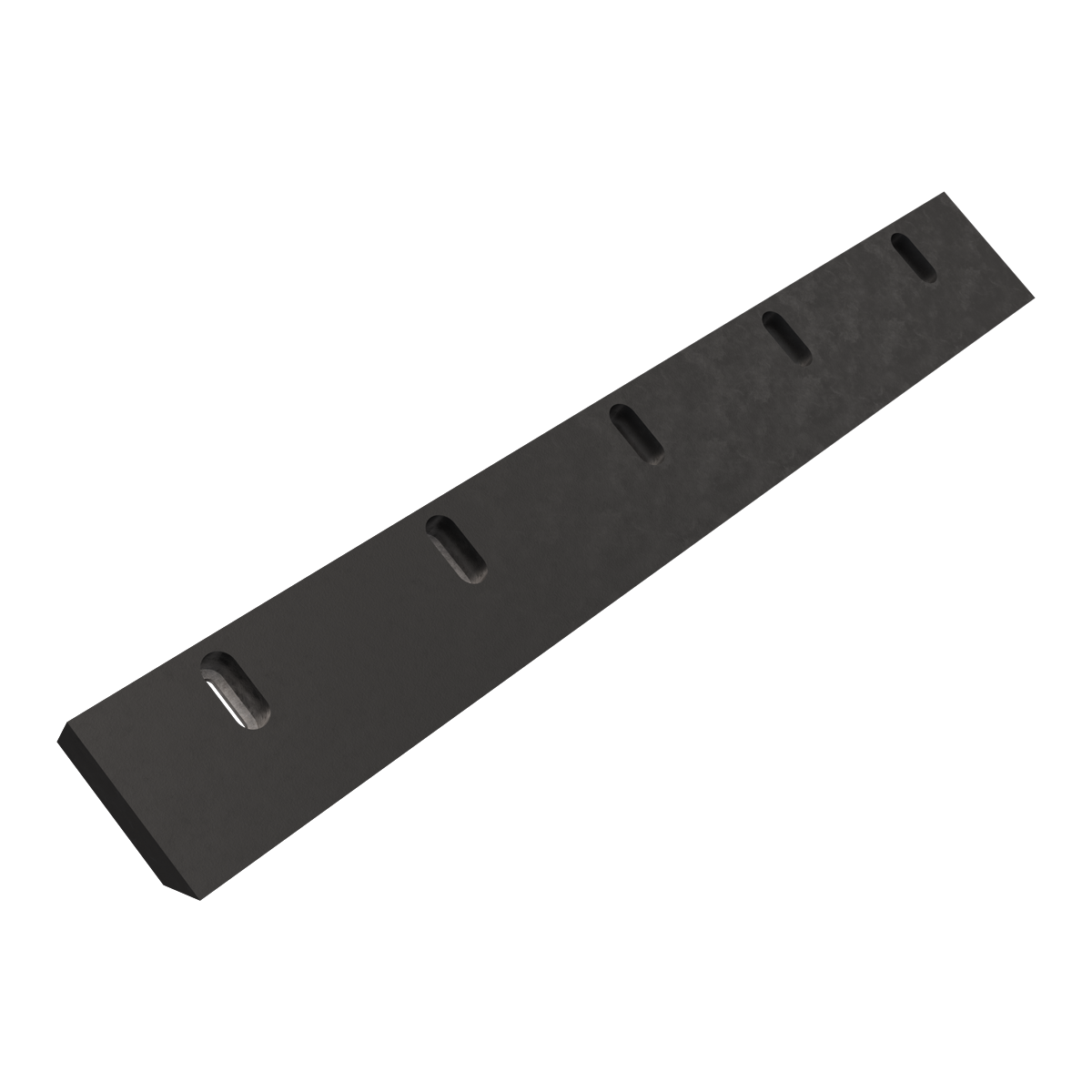

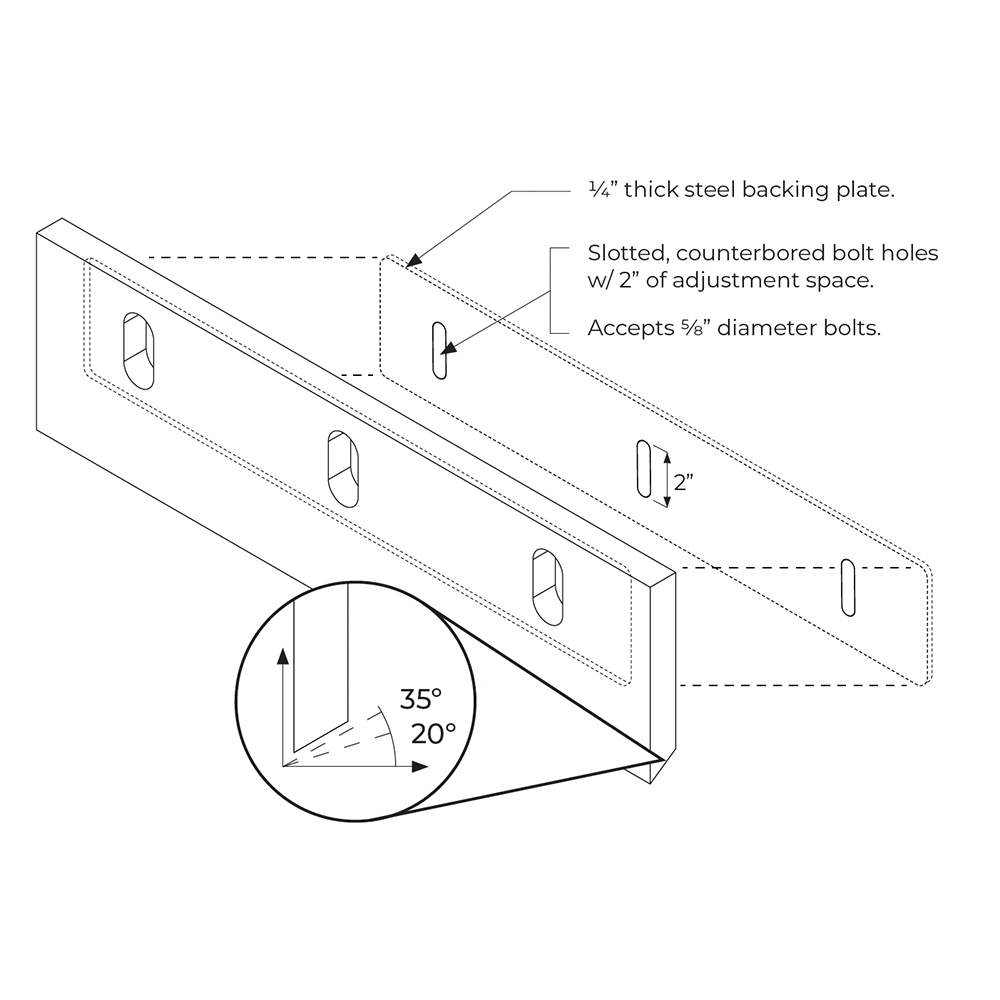

PROTEX CBL

1" / 1.5" / 2"

6" / 7" / 8" / 10" / 12"

48” w/4–20–20–4 spacing at 20º and 35º bevels

48” w/6–12–12–12–6 spacing at 20º and 35º bevels

60” w/6–12–12–12–12–6 spacing at 35º bevel

We guarantee results.

Partnering with Polydeck means more than sourcing industry-leading screening solutions. It’s about working with a team dedicated to technical expertise, operational efficiency, and hands-on support—helping your screening operations perform at their best.

See how Polydeck can drive your site’s success.

Join thousands who screen better with Polydeck.

Years In Business

Sites Using Polydeck

Direct Sales Reps

Global Customer Satisfaction

MINIMIZE SPILLAGE, DUST, AND MAINTENANCE.