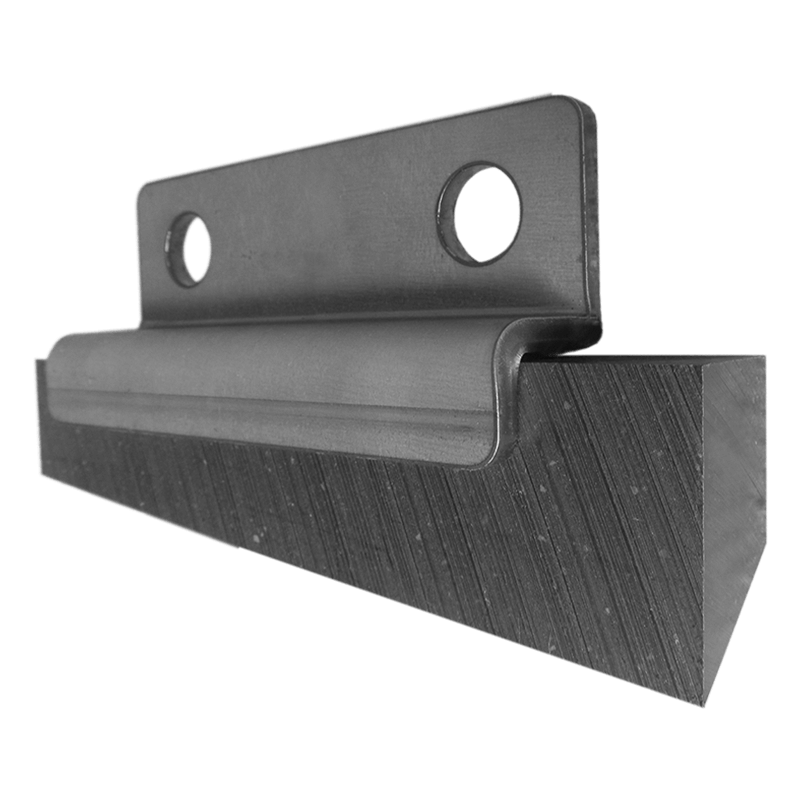

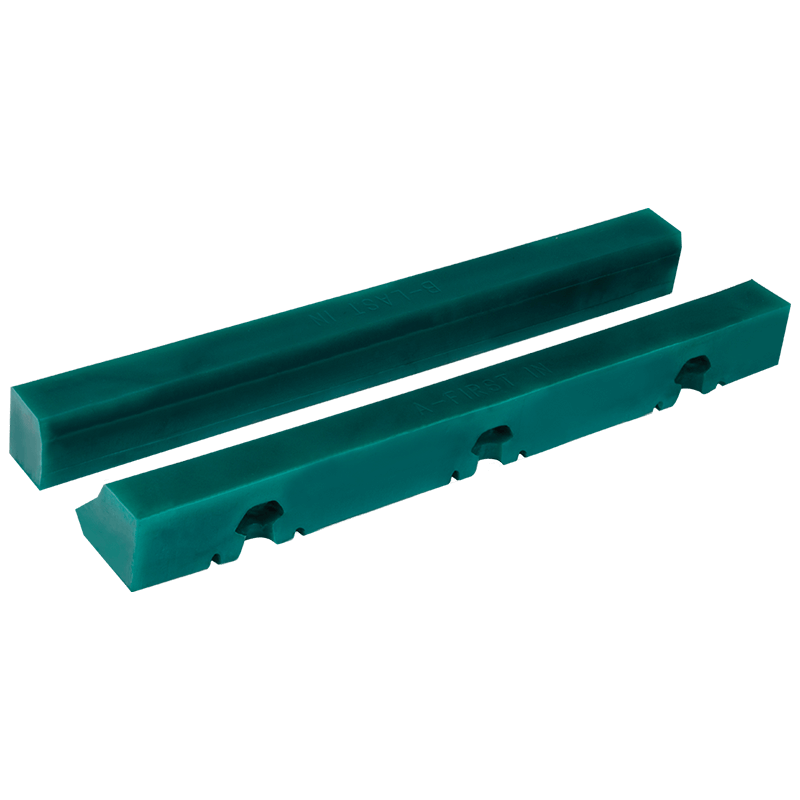

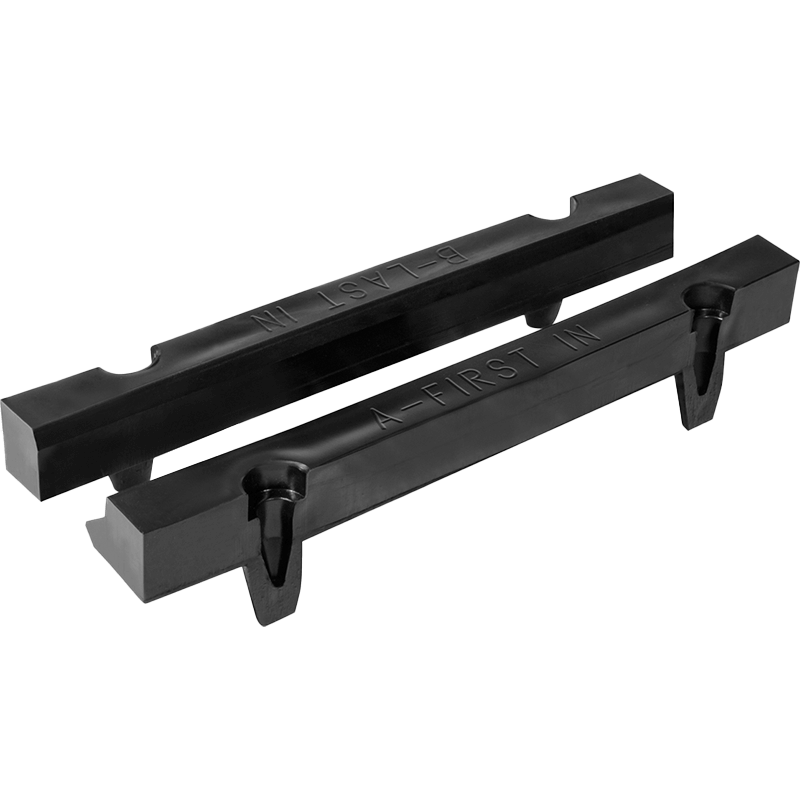

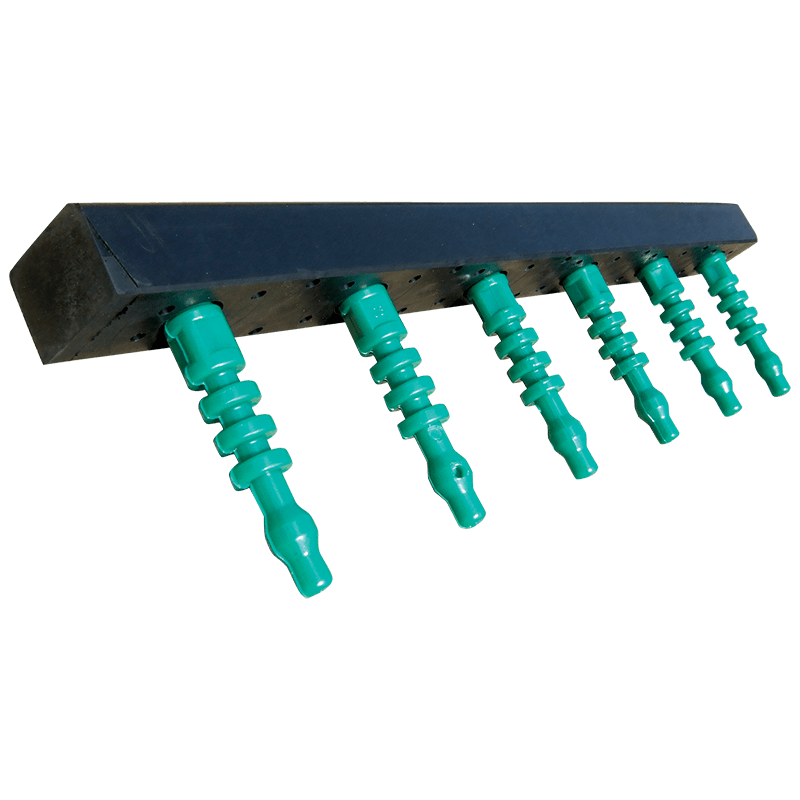

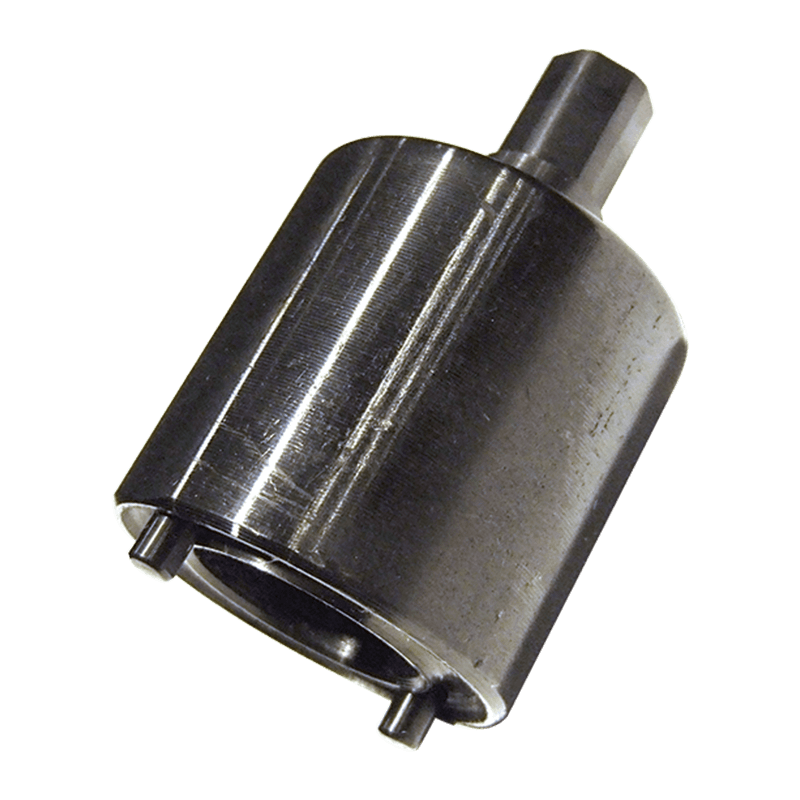

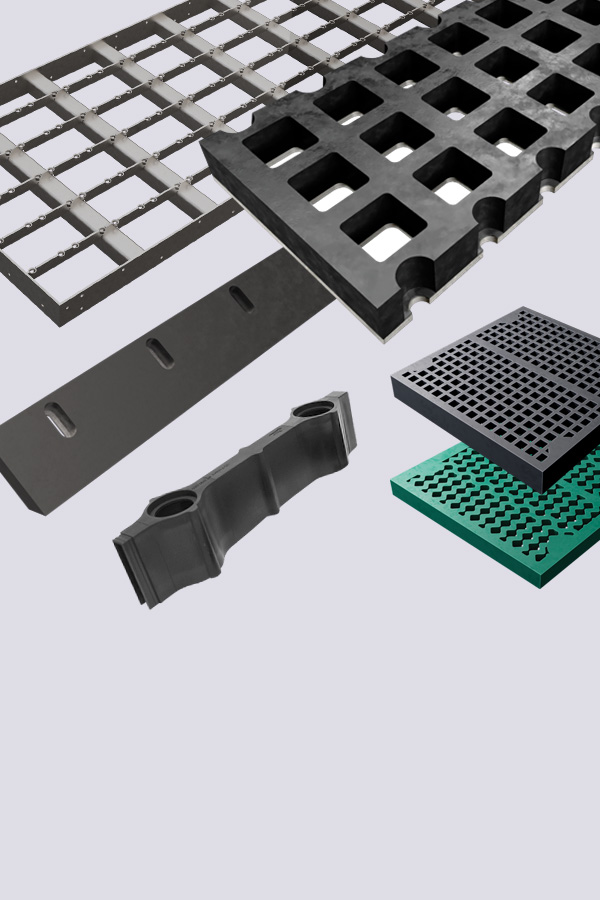

ACCESSORIES

affordable, effective, and durable solutions

Complete your setup.

Fine-tune your screen setup with industry-leading screening accessories from Polydeck. Complete your screening solution with accessories that are affordable, effective, and durable.

Additional Accessories

We guarantee results.

Partnering with Polydeck means more than sourcing industry-leading screening solutions. It’s about working with a team dedicated to technical expertise, operational efficiency, and hands-on support—helping your screening operations perform at their best.

See how Polydeck can drive your site’s success.

Join thousands who screen better with Polydeck.

Years In Business

Sites Using Polydeck

Direct Sales Reps

Global Customer Satisfaction

ACCESSORIES

affordable, effective, and durable solutions.