Maximize your

with a company that cares.

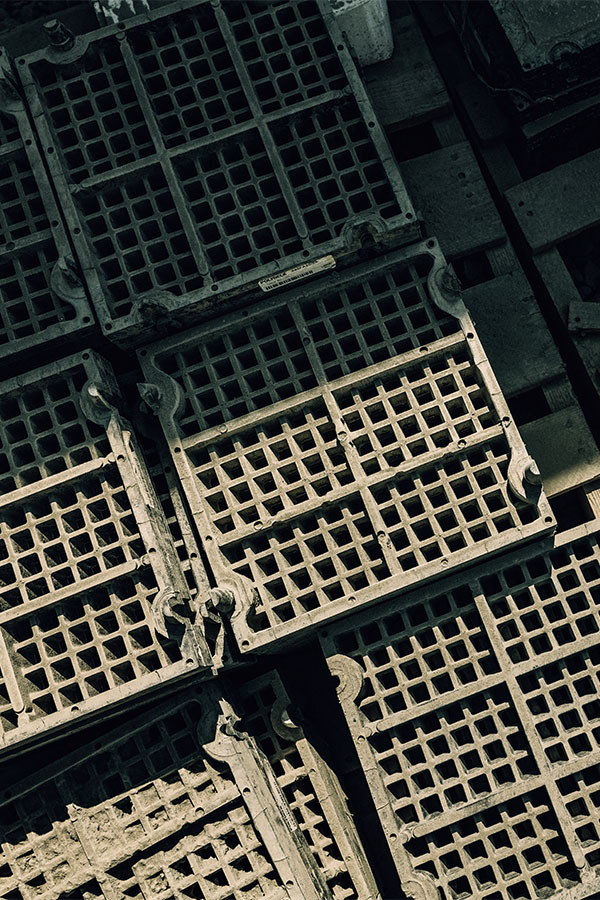

Your partner for all things screening.

Established in 1978, Polydeck has over four decades of experience providing innovative modular screen media and screening solutions for the mining, aggregate, and E&I industries.

We are driven to help our customers optimize their screening processes through product application expertise, precision engineering support, and unmatched product quality.

More throughput.

Longer wear life.

Greater efficiency.

Backed by decades of innovation and experience, every Polydeck product is precision engineered to overcome your most challenging application demands.

The Polydeck Advantage

At Polydeck, we’re more than just screen media and accessories.

We are a strategic partner ready to help transform your entire screening process and elevate it to new production heights.

Results-driven.

Performance guaranteed.

We stand by the quality and performance of our screen media. That’s why all Polydeck screen media are backed by our risk-free performance guarantee.

Discover how The Polydeck Advantage ensures you hit your production goals.

Join thousands who screen better with Polydeck.

Years In Business

Sites Using Polydeck

Direct Sales Reps

Global Customer Satisfaction

Service to our employees and communities is a core part of what Polydeck represents.

Service to our employees and communities is a core part of what Polydeck represents. Opportunities, training, and development are central to being a part of our team.

Opportunities, training, and development are central to being a part of our team. Our Care Team is here to provide physical, emotional, and financial assistance to employees in need.

Our Care Team is here to provide physical, emotional, and financial assistance to employees in need.