Pinto Valley Mine, part of the Capstone Mining Corporation, is currently the only open pit copper mine operating in the historic Globe-Miami mining district of Arizona. As an older plant designed to run a maximum of 48,000-tons per day, the facility has recently focused its efforts on optimization initiatives to meet market demand.

30-year mining industry veteran, Bob Dickey, who has overseen the Pinto Valley Mine for the past three years, is the driving force behind optimizing screening circuits and using high-quality screen media to increase efficiency. When Dickey took over the plant, his main goal was to push as much production through the plant as possible. To do this, he knew he would need to bring in suppliers and partners to boost efficiency at the mine to fuel high-impact, quick-payback results.

For Pinto Valley, the biggest need was to maximize open area on the screen deck to get the desired throughput. “If a screen deck panel lasts six months, but we’re wearing it to a point that oversize is going to the ball mills, then there’s no value in that. Instead, we focus on maximizing the efficiency of those screen deck panels until we reach the targeted wear point that triggers the deck changeout,” stated Dickey.

As he began prioritizing the elimination of bottlenecks within the screening circuits as a quick way to optimize performance, Dickey turned to Polydeck for assistance.

Polydeck’s Mining expert, Tom Wayment, visited Pinto Valley to learn more about the challenges the site was facing with its existing process. Through extensive on-site testing, hands-on follow up, and service, the Polydeck team worked closely with Pinto Valley to “dial in” the screen circuits to meet specific requirements.

“Since Pinto Valley runs six identical screens side by side, Polydeck media could be tested right next to a competitive media brand,” said Wayment. The video testing showed a clear indication that the Polydeck media resulted in a clean bottom-deck oversize being fed to the tertiary crushers.

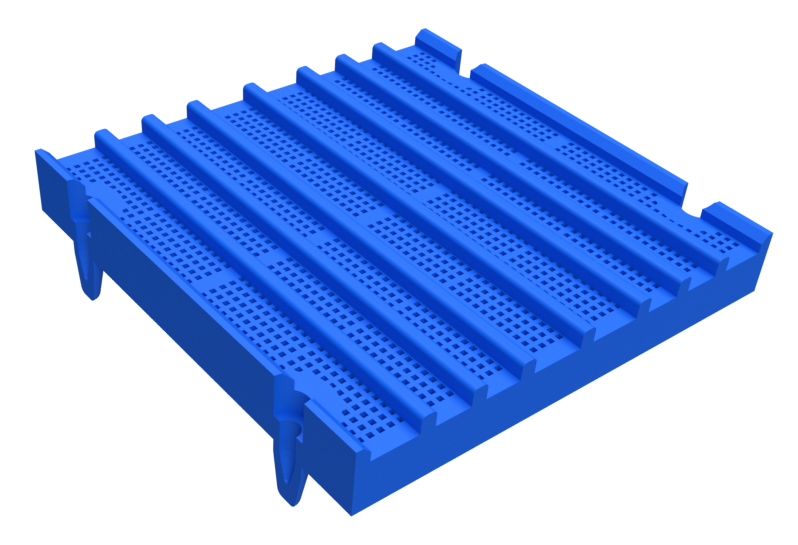

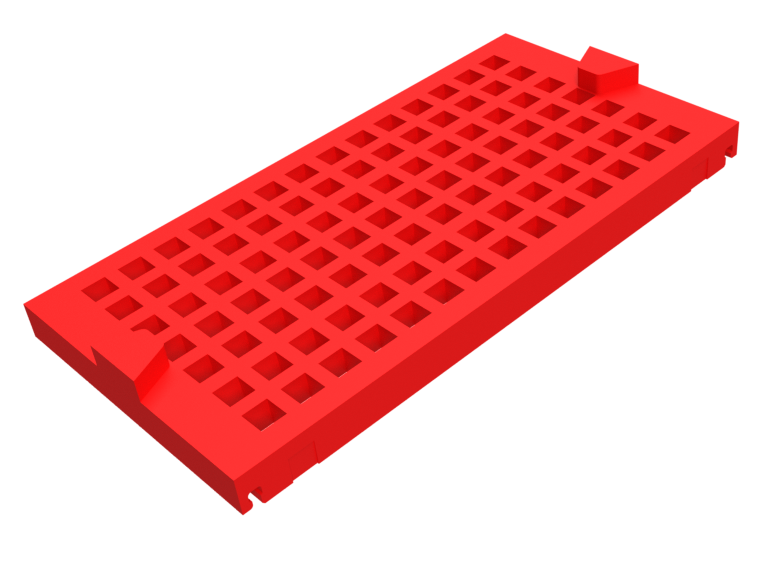

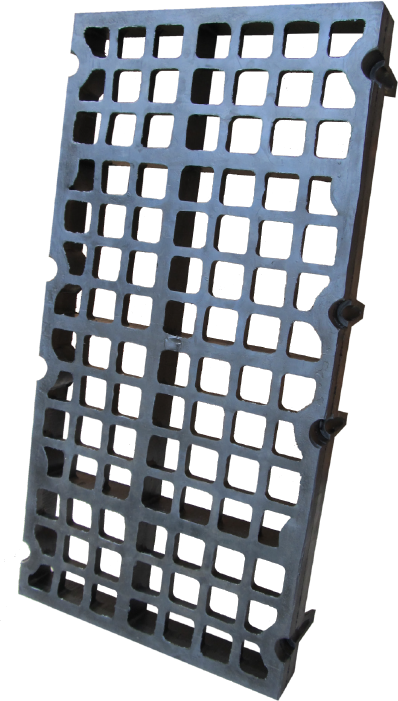

The Polydeck team worked to install a custom layout of Polydeck RUBBERDEX® modular screen media on the secondary and tertiary double-deck screening circuits to increase open area and wear life for greater efficiency. RUBBERDEX XLR® media is installed on the first three rows of the feed end on the top deck. The specially formulated XLR media compound is engineered for up to 15-percent increased wear life in abrasive applications. The remainder of the top deck features RUBBERDEX® panel types that target high-wear or heavy-feed applications. The bottom deck also utilizes abrasion resistant XLR media panels on the feed end, with the remainder of the deck featuring RUBBERDEX® panel types designed to minimize blinding and allow higher material throughput.

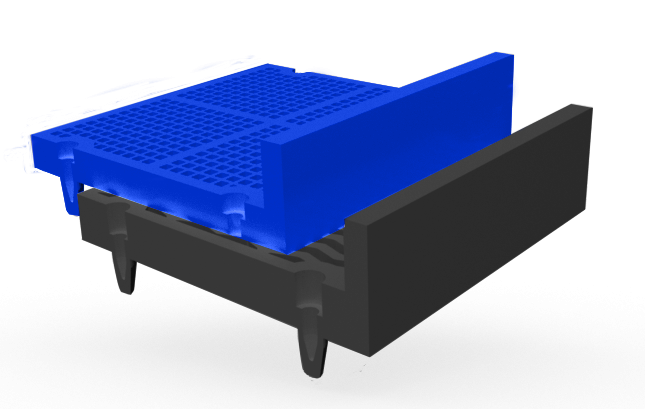

To maximize open area, decks are mounted on Polydeck PIPETOP™ media systems, with narrow ½-inch-wide rails that allow for more openings on the panels, and consequently, more material throughput.

With the help of Polydeck experts and the installation of Polydeck screen media, Pinto Valley increased efficiency to 60,000-tons per day by increasing open area, providing greater screening availability, and maintaining a clean feed being discharged to the crushers. Bob Dickey defined Polydeck as “a true partner, [who helps] to find the ultimate solution – even if it’s not one provided by them”. By consistent testing, evaluation, and tweaking, together with Polydeck, Pinto Valley found a way to combat dated technologies and maximize its operations.

Mining and aggregate operations that utilize Polydeck synthetic media experience many benefits, including a decrease in downtime with a modular system, increased media wear life, and the ability to add surface features. Polydeck surface features can either be integrated into the panel design or added onto the modular system as an auxiliary feature. This article will review molded surface features, which include dams, restricted flow bars, skid bars, and deflectors. Each can play a key role to increase efficiency when used correctly.

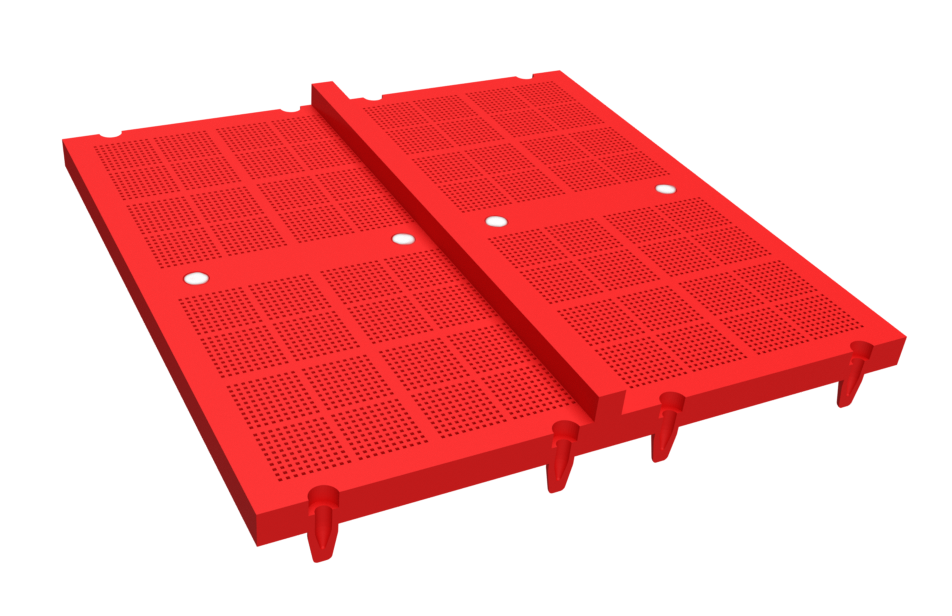

Dams can be molded on both POLYDEX® and RUBBERDEX® media and serve three primary roles: they slow the material flow, help build bed depth, and aid in material stratification. Injection-molded dams come in 1”, 2”, and 3” options. Dams are commonplace in many operations and may be useful to slow material on slurry-fed or incline decks, retain material under spray bars to maximize fines removal and passing of near-size material, or build bed depth in lightly loaded applications. They also stratify the material by agitating and redistributing the fines to the bottom of the material bed.

Pro Tip: For Flexi RUBBERDEX® panels with dams, Polydeck recommends installing dams oriented to the feed end for improved wear life.

Restricted Flow Bars, or Restricted Flow Dams, consist of a multitude of low-profile dams along the surface of the panel; these are oriented across the flow of material and are available with many POLYDEX® panel designs. Similar to traditional dams, these may aid in slowing material across a deck, but they are especially effective in stratifying material.

Skid Bars have similar structural form to the Restricted Flow Bars, but the orientation is with the flow of material. The main purpose for skid bar use is to increase wear life in heavily loaded or highly abrasive applications. These may be added to increase panel rigidity, as well, and are available on both POLYDEX® and RUBBERDEX® media.

Pro Tip: Use Skid Bars as stratification aids. Apertures prone to blockage by oversized material can be cleared by elevating the rocks via skid bars; this allows smaller material to pass through the panel.

Deflectors are small protrusions intended to prevent material from channeling down the panel margins. As the name implies, these deflect the material from the margins to reroute the material over the apertured panel surface. These are highly effective on Polydeck Standard, Extended Open Area (EOP), and Polyrail panels, which carry wider lateral margins to protect channel and tube stringers.

Pro Tip: For many Standard and EOP applications, an alternative to deflector use is converting the deck support to Polydeck PIPETOP STRINGERS; this change significantly reduces the margin and increases open area with Polydeck MAXI and DMAX media.

In conclusion, molded surface features are simple additions that can make notable impacts on the efficiency of many screening operations. The molded surface features smoothly integrate into most Polydeck modular media layouts and are an easy means to mitigate common screening challenges with the change of a panel.

Contact Polydeck for more information or a personalized recommendation on molded surface features and other process improvements.

Written by Jamie Mills, Product Development Application Engineer for Polydeck.

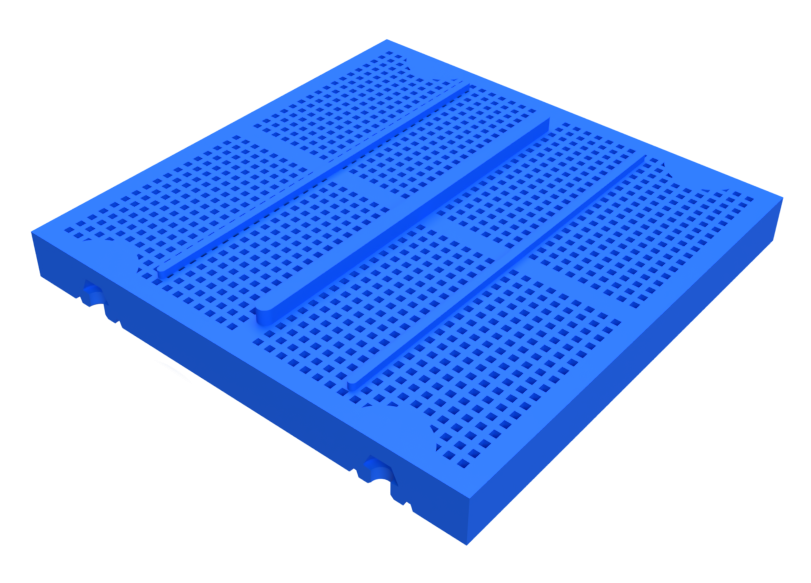

Producers often turn to what has always worked and what they are accustomed to when it comes to selecting their screen media. While wire cloth has its advantages, wire has met its match in Polydeck’s newest offering. Meet DMax, the latest in high performance, extreme open area synthetic modular screening.

At Polydeck, we’re known for relentlessly pursuing solutions to the challenges our customers face. When your operation depends upon the performance of your screen media, nothing less than the best solution is acceptable. DMax, Polydeck’s latest evolution in modular synthetic screen media provides so much throughput advantage, its open area rivals that of wire cloth while providing the durability and benefits often associated with modular synthetic screen media panels.

DMax is the result of Polydeck’s advanced material science technology that balances durability and high open area in screen media construction. This balance provides a better return on investment and a significant increase in throughput where DMax panels are used. Plant Manager Trulane Vanatta recalls the efficiency gained by using DMax panels at Morrison Quarry, “The increase in open area resulted in an 11% increase in the production of profitable 1-in. rock, and reduced fines by nearly 1%.” As any producer knows, even small reductions in fines paired with production increases is incredibly important to an operation’s profitability.

When producers initially began using synthetic screen media, it was in response to the durability the product offered them. DMax achieves the durability producers expect, along with a significant increase in available open area. DMax provides the perfect balance between wear life for uptime, and the health and safety benefits associated with reduced noise and fewer whole deck changeouts. Like all of Polydeck's modular synthetic media, Dmax can be changed out in small sections as screens wear, preventing dangerous and costly shutdowns for larger media changeouts, while preserving the benefits synthetics are known for.

DMax panels are fully customizable, allowing Polydeck’s team of experts to create a solution that meets the unique needs of each operation. Common opening ranges can increase open area by 25-30% against standard synthetics, frequently exceeding wire's actual available open area, which is the open area actually available once bucker bars and other dead spots are accounted for. As every producer knows, open area is directly related to efficiency, thus more open area means a more efficient operation.

A Producer using cone crushers in a closed circuit could benefit significantly from using DMax. The extra open area on the screen preceding the cone crusher allows the product to reach the pile more quickly, instead of the cones. The result is extra capacity for the cone, less fines generated overall, and good salable product to pile sooner and in higher overall splits within the plant. The extra open area provided by DMax means less dust and fines and more clear stone production. This also helps decrease cone crusher wear and reduces overall power consumption since the system is being evacuated more quickly. Reduced power consumption translates to lower operational costs both in energy costs and wear on equipment.

Polydeck’s modular technology allows for easy and safe installation of DMax with other panels and use in zones where efficiency is key. DMax is ideal for use in conjunction with heavier duty panels in feed zones in order to maximize useful available open area.

DMax offers a significant weight reduction benefit over other synthetic screen media options, which reduces component wear on the screen and increases the effect of the vibrating mechanism’s stroke on particle separation. At the end of the day, it all translates to higher production levels with reduced costs.

While there are many applications where DMax can be used, producers win with DMax where there are overall blinding issues or overloaded decks leading to inefficient screening. DMax eliminates blinding and allows for more throughput. With DMax, the right size material goes through the screens, eliminating downstream bottlenecks and increasing tonnage through the plant. When durability, true open area, and reduced downtime come together, efficiency is the ultimate result. Consider DMax, the synthetic screen media that will have you rethinking your wire cloth.

Read about why Polydeck uses injection molding to manufacture our screen media.

Screen media plays a crucial role in efficiently segregating or separating minerals. Without a high-performance, durable screen material, frequent screen changes and unplanned downtime are inevitable. High-quality screen media maximizes run time, operating efficiency and profits while minimizing downtime and maintenance costs.

The Beginnings of Injection Molding in Screen Media Manufacturing

Mining operations sacrifice thousands of dollars in lost revenues due to screen media maintenance issues and inefficient screening. One way to ensure the quality of the screen media is to evaluate the process by which it is made. Although used in manufacturing settings for years, it wasn’t until the late 1960’s that injection molding was first incorporated in the production of screen media. That’s when Manfred Freissle, the Father of Polydeck, engineered a modular synthetic screen media concept and chose injection molding as his manufacturing process of choice.

Advantages of Injection Molding

Modular screen media needs to be consistent in its construction throughout the panel in order to withstand the harsh forces generated in mining operations. At Polydeck, injection molding was chosen as the highest quality option. Other processes like casting produce inconsistent results and rely heavily on an operator monitoring the process. There are no means to effectively inspect the material for proper curing that is non-destructive once the casting process begins. For example, on rubber screen panels, under-vulcanization in the center or over-vulcanization of the outer skin reduces the performance of compression molded panels and therefore compromises screening efficiency. These irregularities led Peter Freissle, Manfred's son, to choose injection molding instead for its consistency, durability, and overall quality versus competitive processes.

Since the creation of the first prototype, Polydeck has continually been committed to research and development of products and methods that lower the overall cost per processed ton for its customers. This uncompromising approach has resulted in screen panels that produce consistent high-quality results every time.

Consistency is Key (and the Proof is in the Product)

Polydeck’s injection molding process involves heating the raw material of proprietary polyurethane or rubber blends into a liquid state and injecting it under extreme pressure into a cavity containing a wide range of mold geometries required to make each specific product. These components and geometries allow a myriad of combinations relating to the aperture size and shape, fastening type, and surface features, while producing panels that minimize any trapped air and/or voids inside the panel which compromise integrity. The entire process is carefully calibrated and computer controlled to monitor key process indicators from panel to panel, minimizing operator errors, and ensuring consistency.

As a privately-owned company focused solely on effective screen media solutions, Polydeck has the flexibility and a range of more than 1,500 screen panel design options to suit virtually any screening need. The injection molding process can produce panels in minutes, not hours, enabling the company to feature the shortest lead time in the industry on non-stock screen panels. By using superior materials during manufacturing, Polydeck is able to ensure consistency in construction and repeatability from panel to panel. This means more product can be screened, leading to higher payouts and an overall more efficient screening process.

Ultimately, when choosing screen media, producers should consider the quality and value of the media, and base their decision on the overall costs saved over the life of the screen panel. Compared to media options sold at a lower cost, Polydeck screen media offers a range of time and cost-saving benefits that no one else can offer.

To learn more about Polydeck’s injection molding processes and how you can save money and screen materials more efficiently, contact a Polydeck screen media expert today!

There’s an old saying that goes: “If it isn’t grown, it has to be mined.” That’s not entirely true, but it makes you wonder what items don’t fit into either of those categories. Keep reading to learn more.

Mining has been and always will be critical to our civilization. This is especially true in our technology-driven age, in which the mining of “Rare Earth Elements” has taken on special significance. You’ve likely read news stories about Rare Earth Elements in recent years; so, what are they and why are they so important?

Rare Earth Elements are instrumental to our modern world.

When people think of mining they typically think of coal, copper, or gold mining, but all sorts of raw materials are mined from the earth. Because the mining industry is so widespread, it is a hotly-debated topic among politicians, environmentalists, and communities around the world.

More recently, the attention focused on the mining of Rare Earth Elements has grown rapidly in global scale and impact. To start, there are 17 Rare Earth Minerals grouped together on the Periodic Table of Elements: cerium (Ce), dysprosium (Dy), erbium (Er), europium (Eu), gadolinium (Gd), holmium (Ho), lanthanum (La), lutetium (Lu), neodymium (Nd), praseodymium (Pr), promethium (Pm), samarium (Sm), scandium (Sc), terbium (Tb), thulium (Tm), ytterbium (Yb), and yttrium (Y). Despite their mysterious name, however, not all of them are truly “rare.”

What makes them so important, or as we call them, “rare,” is these materials are found in one form or another in virtually every technological device on the planet. Without them, the modern world as we know it could not exist.

Rare Earth Elements help us “Go Green.”

The big tech push right now is in “going green” through electric vehicles and sustainable energy sources. One Rare Earth Metal in particular—neodymium—is used to produce strong magnets for electric motors and turbine generators. Many rechargeable batteries are also made with Rare Earth Metals, such as lanthanum, cerium, promethium, and neodymium.

Rare Earth Elements are the future.

From cell phones and aircraft engines, to MRI machines that save lives every day, Rare Earth Elements are integral components to the evolution of technology and the future of innovation. To date, China is the largest producer of Rare Earth Elements, but that is beginning to change. With the price of metals from China increasing, and a growing recognition among world powers that Rare Earth Elements are strategic resources, many other nations are ramping up domestic production capacity, both to meet the skyrocketing demand and to ensure a stable supply.

Here in the US, Polydeck is currently helping a new mine in Nevada produce Rare Earth Metals. Australia, Brazil, and India have all recently ramped up production as well.

The future is bright for Rare Earth Elements and mining them is definitely a growth industry for the foreseeable future so long as we keep using cell phones, driving electric cars, and using the latest devices.

Written by Tod Eberle, Director of Aggregates for Polydeck.

Part 2 covers extending the life of your equipment and maintaining operations by being proactive with maintenance and quality control.

In Part 1 of this two-part series, we reviewed some of the many decisions that must be made before selecting the right screening solution for your operation. Asking the right questions upfront can really pay off over the life of your equipment, once you’ve made the investment.

Part 2 below looks at how to extend the life of your equipment and maintain smooth operations over the long-haul by establishing a system of proactive maintenance and quality control. With such a system in place, you achieve greater visibility over your operational performance and can identify emerging issues before they develop into major problems.

Proactive Maintenance

A schedule of regular maintenance is the best way to ensure that your screening system operates reliably, with a longer wear life, consistent specification accuracy, minimal downtime, and maximum cost efficiency.

Whether you use wire cloth or a synthetic option, periodic visual inspections of your system are necessary to detect any extreme or unusual wear.

- Check synthetic screen decks for wear patterns possibly caused by a change in feed rate, uneven material distribution, or high-pressure water spray. Replace worn screens immediately to prevent out-of-spec material or damage to the fastening system or steel support structure.

- Make sure side-tensioned media screens are tensioned correctly upon installation, and be sure to support side-tensioned synthetic screen decks with high-quality bucker bar rubber. Check them on a regular basis, looking for loose clamp bars or blocked apertures that are plugged with material or blinded over, and re-tension the screens where needed.

- Examine side wear liners as they typically last longer than the actual screen surface, looking for wear and for loose bolts or clamping hardware. If all liners are not securely tightened, the screen panels can move, and potentially damage the side wear liners, the screen panels, or the modular support structure itself. Loose side wear liners can also allow screen panels to disengage, causing material to go out of spec.

When replacing modular synthetic media, ensure a secure attachment to the frame by cleaning sand or fines from the frame surfaces and the fastening cavities.

Regularly evaluate your screen equipment for unusual variations in operating parameters, such as acceleration, displacement, deflections, and critical frequency, all of which can hinder screen performance and even seriously damage the support structure.

It’s also important to work closely with your screen media manufacturer to perform a screen analysis on the machine itself, in order to isolate the possible cause of poor screening performance. Don't forget that Polydeck offers screen performance evaluations and we're ready to help.

Quality Control

Frequent quality control sampling to detect spec changes—either sudden or gradual—is an effective method to monitor the wear life and condition of your screen media.

With modular synthetic panels, the maintenance crew should always be looking for any wear before it becomes a contamination problem. If the quality control team detects gradation changes, however, they can also alert the crew to start gauging the screens and check for any unseen wear issues.

Replace affected modular synthetic media when a product gradation begins trending to the high or low end of the spec range. It takes just a few minutes to change out any worn screen panels and resume operation.

No matter what screen media you deploy, it will eventually succumb to the wear-and-tear of everyday use, not to mention the common operational hazards of the industry.

Selecting the right screen media for the job, and then performing proactive maintenance and quality control tasks, are the best strategies for maintaining optimal performance. By repairing or replacing worn components before they fail, operations can ensure the day-to-day reliability of valuable processing equipment while meeting or exceeding production goals at the same time.

To help you get the most out of your synthetic media, we've created a downloadable checklist for you. Click the link below to get your copy.

Control the quality of aggregate being produced by using modular synthetic media.

Most operators already know there are huge benefits to synthetic media in terms of wear life and cycle cost, as well as better maintenance efficiency due to the ease and speed of changing out worn modular panels. They’re probably also aware that the panels are easier and safer for crews to work with on a deck.

What can often escape the conversation about modular synthetic media, however, is just how tightly the operator can control the quality of aggregate being produced—and what that reliable quality means to not only the aggregate’s producer, but also the end-users.

Consistency is king!

Talk to any end-user of aggregates—such as a concrete or asphalt plant—and its virtually certain that a key factor in their success isn’t simply spec product; it’s also consistency of product.

Sure, end-users can adapt to different gradations of aggregate by adjusting their blends, but this changes their product, too. If the aggregate gradation is consistent, then so is the product being made with it. This, in turn, provides reliable and predictable performance materials for whatever the application may be.So, why do synthetic modular panels ultimately produce a more predictable pavement, bridge, or foundation?

Roller coaster or train ride?

Take wire cloth, for example. Its cut size can change rapidly during production because when wire cloth wears, it tends to break sections open and contaminate the product with oversize aggregate. Along the way to failure, wire cloth’s shallow profile also means that it’s quite common for oversize pieces to filter into the pile through worn openings, creating inconsistency issues.

Because wire cloth creates such rapid trend changes in quality control, there remains a high potential for oversize failures unless aggregate producers are extremely vigilant and change large sections of the screen deck before it fails.

The quality trends produced by modular panels are smoother and more reliable, without the same dramatic shifts up and down. This is due to the vastly improved wear rates of synthetic panel modules, and their tendency to slowly coarsen aggregate rather than “blowing open” and contaminating the product like wire cloth can do.

Such consistent reliability allows modular panel users to effectively monitor their screen media’s condition through quality control reports, instead of just relying on visual or maintenance inspection.

Custom blends

A modular panel setup also allows an operator to produce custom products with drastically more control.

For example:

An aggregate plant deploys an 8-ft. by 20-ft. wire wash screen, comprised of five 4-ft. long sections. If a customer comes to them needing a modified product, then that plant can only make changes in increments of 4-ft. runs—or just 20% of the screen’s area—at a time. Ouch!

Often, this can have too much or too little of an effect. Modular panels allow these changes to be made to the exact degree necessary, in the appropriate portion of the screen, at increments of 0.625 percent!

Ultimately, with synthetic modular panels, an operator can stop worrying about quality control and start using it to their advantage, turning customer complaints and job site fines into customer satisfaction.

Written by Alex Caruana, Aggregate Territory Manager for Polydeck.

Addressing the top 5 most frequently asked questions about screening.

1. I think there’s something wrong with my screen, but I don’t know if it’s worth calling in a professional to diagnose it – what should I do?

There are some visual or field tests you can run to see if it’s worth investigating a screen further. Two easy tests are:

- Travel rate. Paint 2x oversize stones, drop them onto the top deck (loaded and running) simultaneously and observe. If they travel in parallel and come off the screen together, that is a good thing. Timing the travel is valuable to let you know if your screen is running too fast or slow, too.

- Stroke/Displacement. Take a magnetic stroke card measurement of your machine at the vibrator as well as in the corners – on both sides. You’re looking for consistency between sides primarily. Deviations of more than 5% indicate a problem you should investigate further.

You can also list the symptoms of your suspected issue and give us a call!

2. How do I make my Quality Control easier to manage from a Production point of view?

Firstly, communicate! Establish clear and open understanding with your QC staff, give them a plant tour, take a tour of their world too… it’s amazing what happens when you learn about each other’s processes. Secondly, make your screening circuit as stable as possible. Eliminate stop-gap or temporary solutions like patches and silicone on screen media.

3. How do I increase my production rate?

Diligence. Observe and even out feed points, use the right combination of screen media to only apply heavy-duty media in high wear zones and high open area media on other zones. Spend some time looking at bed depth on each deck and whether the stroke is appropriate for each application. Most of the time, some patience and trying one variable at a time to see the effect is highly rewarding.

4. My media is pegging, what do I do?

First, make sure your screen has enough stroke to clear the pegging particles. Remember, you need to manually clear the pegged particles before truly knowing if a change in stroke will prevent this. If this doesn’t work, there are highly successful self-cleaning types of media in all forms – wire, rubber, and polyurethane.

5. How do I set up my spray nozzles?

Set up spray nozzles pointing at 45 degrees against the flow of material. The resulting spray should form a continuous water curtain across the screen, such that material cannot sneak through any weak spots. Working with a screen expert can help determine how many spray bars, nozzles per bar, and spacing from the deck are required, along with volume and pressure balance. Once you see a proper nozzle setup, it's easy to apply throughout your screening circuit.

**These Frequently Asked Questions were collected from a presentation by Aggregate Territory Manager, Alex Caruana. If you'd like a more in-depth online training session for your operation, feel free to contact us.

Additionally, we have provided several resources below for your convenience.

The future (and fate) of the coal industry hinges on constant innovation and the adoption of smarter, more efficient ways of doing business. Industry Expert, Ron Bennett, talks about the most effective measures needed to adapt to coming changes.

Ron Bennett has spent most of his life around coal. After working in the magnetite industry for 25 years he joined Polydeck 17 years ago in a sales position. Today, he is a Senior Industry Expert with the company, where he puts his depth of knowledge and years of experience to use as the lead application advisor for their entire coal division.

In addition to overseeing fleet and safety responsibilities, Ron works closely with Polydeck’s customers in the energy and industrial industry to help develop groundbreaking solutions to their production challenges. His advice is critical in helping both Polydeck and its customers decide on the most effective courses of action to take in response to new trends and shifts in the industry.

Lately, he’s been keeping his eye on the plummeting price of coal and thinking about what it might mean for the future of energy production in the US—particularly the costs of doing business for coal processors.

“Demand is at a near all-time low,” Ron notes grimly, “The price has bounced back a bit from the record warm winter we saw last year, but there’s still lots of stockpile on the ground and parts of the country saw a mild winter again this year. The price is currently around $40 a ton for steam coal and $85 a ton for metallurgical coal—and that’s not good. We’ve already had two major coal companies go bankrupt as a result, so the domestic industry today faces a huge challenge.”

Despite the downward trends, Ron sees opportunity for processing plants to shift their cost burden in a positive direction by making operational changes that reduce their processing costs. These costs include a variety of production factors, such as planned or unplanned downtime, screen efficiency, proper sizing, magnetite recovery, and maintenance. Every point of improvement has some effect on an operator’s overall costs; collectively, however, they can have a tremendous impact on the bottom-line.

The energy and industrial team at Polydeck has over 150 years of industry experience and they understand the difficulties operators face in bringing production costs under control. As Ron puts it, “If someone has a coal issue, you can be sure we’ve dealt with it before.”

Polydeck relies on the team’s combined knowledge and their strong relationships with its customers to help the company design and manufacture innovative products that drive those costs down.

Reducing Costs on the Scalping Screen

Raw coal scalping can be a problem when there is a high presence of clay in the run, which makes the coal “sticky.” As the coal passes through the screen deck, the clay adheres to the screen and clogs up the apertures, slowing the production flow and creating inefficiency. Eventually, the run has to be paused while a crew clears the screen deck of clay—a costly work stoppage by any measure.

“I’ve seen an operator have to shut down three times in a single shift to clean their deck,” Ron recalls, “That makes the run really expensive to clean, process, and put in a car. These days, that just won’t cut it.”

To address these types of applications, Polydeck developed specialty rubber products. Because the rubber panels are extremely flexible, they shed the clay and maintain the screen’s efficiency. Not only does the pass-through volume stay consistent, but by not having to shut down the screen to clean off the clay, the operator also saves a lot of downtime and labor costs.

Polydeck’s polyurethane products for raw energy and industrial applications similarly reduce maintenance and downtime costs by providing superior wear life and fast, easy change out. These products are a direct result of Ron and his team working closely with customers to understand what they need their equipment to do.

Reducing Costs in Drain-and-Rinse Applications

Drain-and-rinse applications wash magnetite off coal and allow operators to recover the material, which is important because magnetite prices are at an all-time high. Just a few years ago, magnetite sold for around $90 per ton. Now, because magnetite is no longer domestically produced, the import and shipping costs—along with a lack of competition—have driven up the price to over $300 per ton.

This makes magnetite recovery a profitable task, but it also presents a completely different challenge for processors. In this case, particularly, getting the correct size distribution on the screens is critical to ensuring that the maximum amount of magnetite product is recovered.

To ensure proper sizing and drain rates, Ron advises clients to adopt a solution that incorporates Polydeck VR panels on the top deck with continuous slot panels or profile wire panels on the bottom decks: “The easy change out can dramatically lower an operator’s maintenance costs and decrease their downtime.”

Reducing Costs in Recovery Applications

Consistency is key in any business, but it’s of extreme importance in the fine coal circuit, where recovery can come down to a mere .02 mm difference in size. Ensuring consistency gives the operator the confidence that they’re putting 100 percent of their product on the ground and not throwing away valuable product due to inefficiency.

“Producing consistently sized panels is one of Polydeck’s core competencies, and it’s a strong selling point for our products” Ron explains, “All of our rubber and urethane panels are manufactured with an injection-molding process that produces a consistent aperture size from panel to panel. We even back it up with a product performance guarantee: If our panels are ever not to the customer’s spec, we’ll replace them at no cost.”

Reducing Costs in the Supply Chain

An often overlooked area in which an operator can reduce their operational costs is in the ordering and fulfillment phase of supply inventory. An operator who partners with a supplier that has sufficient warehousing and logistics can keep less stock on site and instead rely on rapid delivery of replacement stock to maintain profitable production levels.

Again, Ron points to Polydeck as a good example of the type of partner an operator can leverage to help reduce their costs: “[Polydeck’s] products are manufactured in Spartanburg, SC and stored in three distribution centers strategically-located in the eastern US coal fields—in Morgantown, WV; Chapmanville, WV; and Ridgeway, IL. Additionally, Polydeck has strategic partners in Eastern and Western Canada who store product for customers so that they are on hand when needed. This means that we can guarantee availability of product and fast delivery to the customer—usually by the next day. It also means the customer can save more money by reducing their stocked product levels.”

The Future of Cost-Savings

Ron regularly sees the benefits of greater efficiency when dealing with customers. “The maintenance savings alone with a modular deck is substantial,” he explains, “I was working with a processing operation to help them transition to a new modular Polydeck screen. While I was there, the supervisor and I watched his crew change out their old metal screen. It took four guys with torches and impact tools several hours to do the work.”

This kind of downtime and labor-intensive maintenance was killing the client, but with a new Polydeck screen, it would only take a single team member a few minutes to swap out a 1x1 panel. After installing the Polydeck screen, the customer saw a dramatic improvement in the entire plant.

“When I went back,” Ron says proudly, “the supervisor told me to walk the plant and report back what I found. The facility was the cleanest I had ever seen, and the entire production was running smoothly. When I told him so, he said, ‘That’s exactly what I wanted you to see; my guys have more time to take care of other things instead of constantly replacing screens.’”

This is the sort of opportunity for change and improvement that Ron sees taking place for operators across the country. “The industry is going through a sea of change as the world transitions from traditional fossil fuels to other forms of power generation. Just last year, coal dropped below 50% of all forms of power generation for the first time.”

He remains positive about the future, however. “Look, everyone needs to remember that coal still keeps the lights on. Despite all the changes around us, coal isn’t going anywhere for the time being.”

Coal processors know that they have to make changes to adapt to the new realities in order to remain profitable. The easiest way to do that is to examine their operation from top-to-bottom, find those areas where improvements can be made, and then partner with vendors who can help them implement those improvements.

Without the capacity to overcome production bottlenecks and inefficiencies, increase the productivity value of their work force, and maximize the quality and consistency of the product throughput, processing operations could be forced to shutter if the cost of coal continues to drop.

The good news for operators is that they aren’t alone. Companies like Polydeck, and experts like Ron Bennet and his team, work hard to come up with solutions to the production challenges facing coal processors. They know that the future (and fate) of the industry hinges on constant innovation and the adoption of smarter, more efficient ways of doing business.